Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

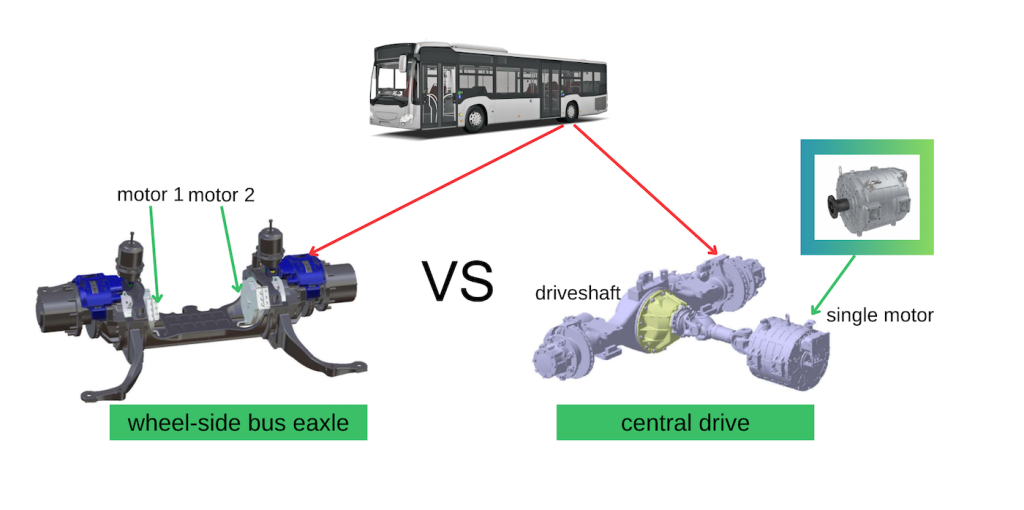

Electric Bus Wheel-side eAxle technology is reshaping the design of electric buses. Unlike traditional central drive systems, the wheel-side axle places the electric motor close to the wheels, transmitting power directly through reduction gears. This distributed drivetrain design reduces mechanical complexity, improves energy efficiency. It allows bus manufacturers to build e-buses with flat floors and more inner space. As many cities demand cleaner and more efficient transit solutions, wheel-side drive axle are becoming the preferred choice for electric buses worldwide.

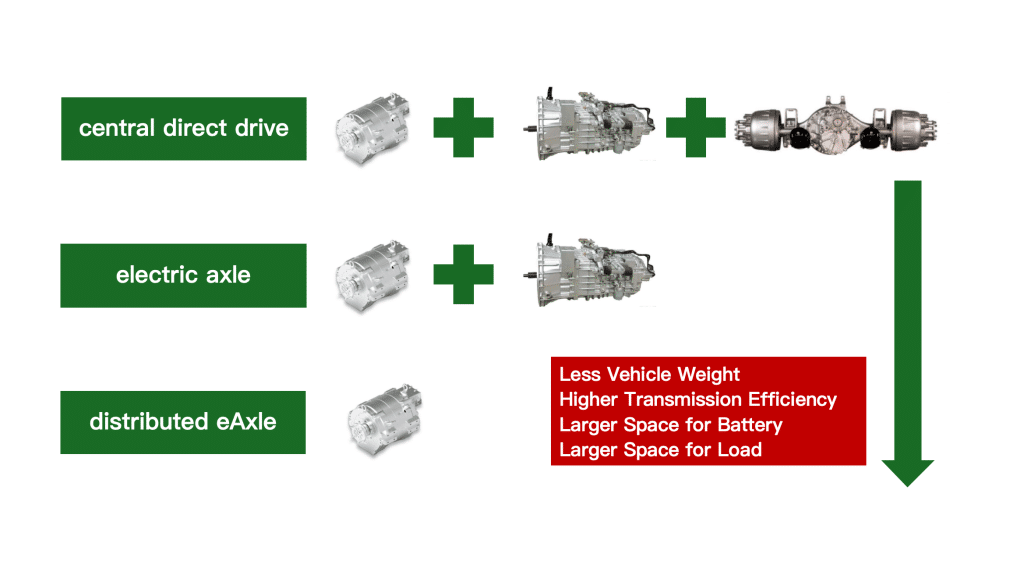

Traditional electric drive systems used a motor connected to a conventional axle with a driveshaft and differential. This central drive system could integrate with existing platforms without to many changes to the chassis, front and rear axles or differentials. But it has limitations in heavy transmission components, complex layouts, and restricted cabin design.

Electric portal axles change this completely. By removing the driveshaft and positioning motors directly near the wheels, buses can achieve a fully flat low-floor layout. This makes boarding faster, increases cabin capacity, and improves passenger safety by eliminating the raised rear section common in traditional buses.

| Motor near the wheel | Each motor and reducer sits close to the wheel end, shortening the power transmission path. |

| No driveshaft | Eliminating the long driveshaft makes the structure simpler and lighter. |

| Compact axle housing | The axle integrates both load-bearing and drive functions, reducing intermediate parts. |

| Distributed drive | Each wheel can be controlled independently, enhancing performance and safety. |

✅ Enhance Safety and Passenger Comfort

Wheel-side eAxles eliminate the raised rear section of buses, giving passengers safer movement inside the cabin.

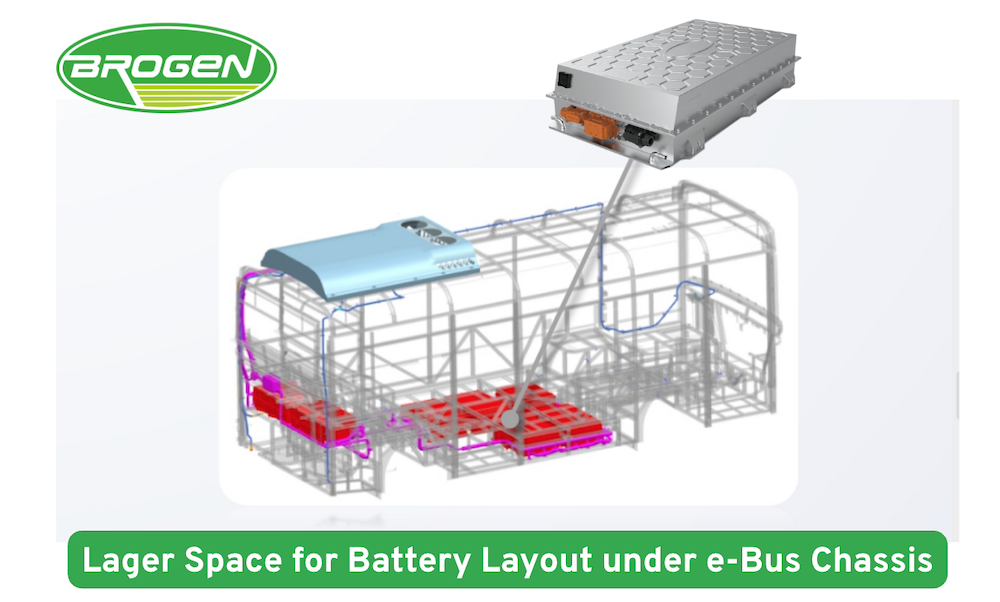

✅Low Floor and More Space

Because the traditional bulky drive shaft and central motor are eliminated, the chassis can be completely flat and low-floor, resulting in a larger cabin and convenient boarding and alighting. Therefore, bus wheel-side axles are ideal for low-speed, frequently stopped and started city buses, particularly those with flat floors. They are also well-suited for sanitation vehicles and airport shuttles, which have low profiles and require frequent boarding and unloading.

✅Lightweight Design

By removing heavy components such as the driveshaft, Wheel-side eAxles reduce overall vehicle weight. Compared to central drive systems, weight savings can reach up to 200 kg, directly improving energy efficiency.

✅High Energy Efficiency

Fewer transmission links result in low energy loss and high energy recovery efficiency, making them suitable for frequent stop-and-start bus operations.

✅Extended Battery Space

Without a driveshaft and bulky gearbox, the chassis gains more usable space. Manufacturers can install more battery capacity, increasing bus range without sacrificing passenger room.

✅Cost-Effective Operation

The design reduces energy losses and wear, lowering long-term maintenance and energy costs. Operators save on both fuel-equivalent expenses and service downtime.

✅Independent Control and Stability

Each wheel operates independently. Advanced control systems adjust slip ratios of the left and right wheels, reducing tire wear and improving traction on slippery surfaces. Functions such as anti-slip regulation (ASR) and electronic stability programs (ESP) can be achieved without added cost.

BYD K9, a fully electric bus manufactured by BYD, has installed the Wheel-side eAxle. The K9 is a popular choice for cities and campuses worldwide, offering a comfortable and eco-friendly alternative to traditional diesel and CNG buses. This model integrates wheel side drive and regenerative braking in a low-floor design.

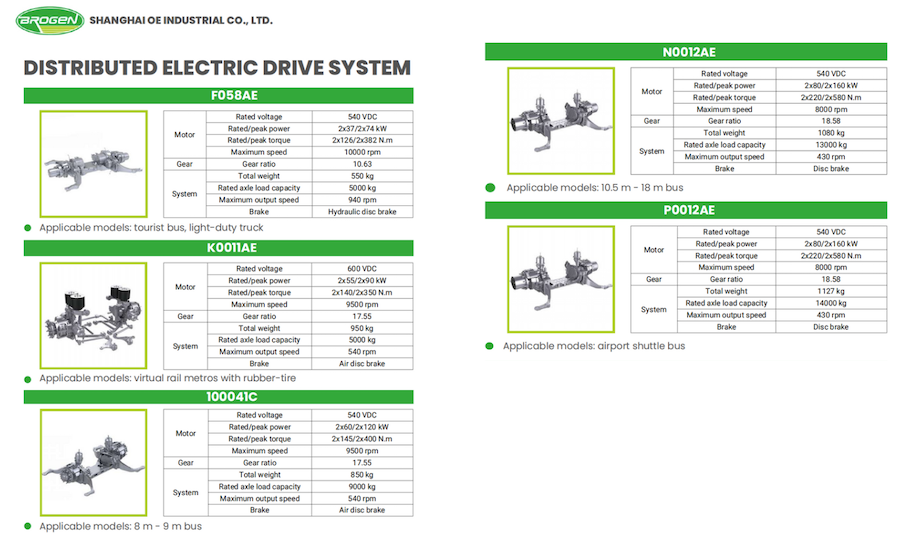

Brogen offers state-of-the-art distributed drive electric axle systems designed specifically for electric buses. Our system uses dual-motor wheel-end drives for compact integration, high torque, and precise control.

Brogen’s Wheel-side eAxle solutions have been tested across millions of kilometers, ensuring proven reliability for public transport operators. Let's take a look at Brogen's electric wheel-side axle for electric bus.

The Electric Bus Wheel-side eAxle is not only a technical innovation but also a commercial advantage. It offers safety, energy efficiency, lightweight design, and improved passenger experience. Brogen’s advanced solutions provide OEMs with a reliable pathway to build next-generation electric buses that meet global standards for performance, efficiency, and sustainability.

For bus manufacturers looking to lead in the electric vehicle era, adopting wheel side drive technology is the key to step forward. Find more about Brogen's electric drive axle solutions for commercial vehicles.

Brogen is a leading ev solutions provider for commercial vehicles and boats. Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube. Find more about Brogen's ev solutions for commercial vehicles.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Company Profile