Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

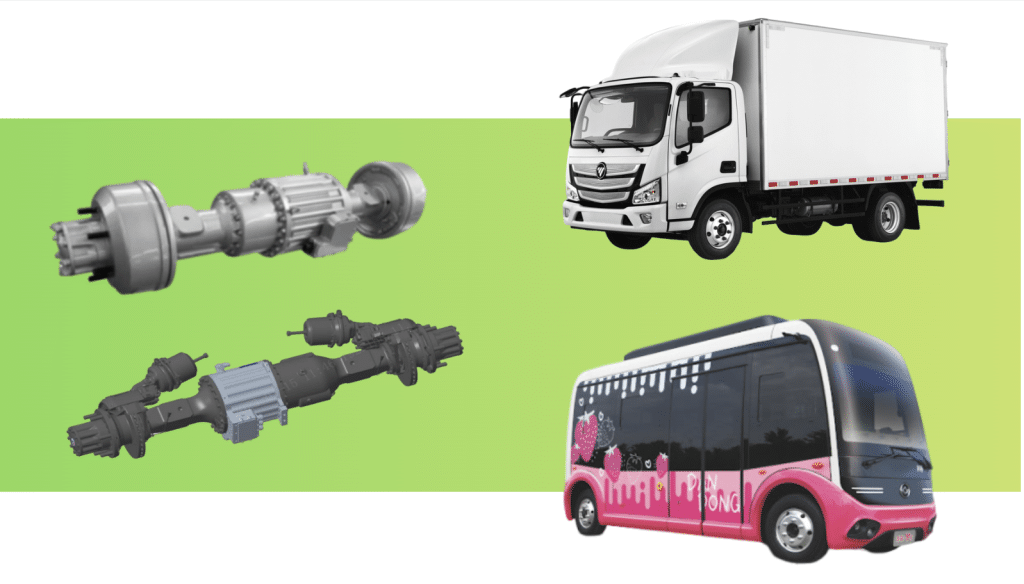

The Coaxial Electric Drive Axle is becoming one of the most important drivetrain solutions for pure electric light trucks,vans and buses.

Unlike the traditional gasoline drivetrain, which relies on an engine, clutch, transmission, driveshaft, and drive axle, this integrated system simplifies the structure and improves efficiency. In the early stage of electric truck development, engineers tried to replace the engine and transmission with a motor and reducer. That method was costly and inefficient. As the market grew and technology advanced, manufacturers started to pursue lighter, more compact, and more efficient systems. The coaxial electric drive axle provides these benefits, and many pure electric micro and light trucks now use it as a standard solution.

Above is schematic diagram of motor placement for direct drive, coaxial electric drive axles, and parallel axis electric drive axles.

Above is a coaxial electric drive axle for pickup truck.

The coaxial electric drive axle consists of a electric motor, planetary reducer, differential, and axle housing, all arranged coaxially as a single unit. This compact design shortens the drivetrain, reduces the number of components, and lowers overall system weight. It performs load-bearing, driving, and braking functions, converting electrical energy into mechanical energy to drive the wheels. By combining the motor, speed reducer, and differential into one package, it delivers a lightweight, efficient, and cost-effective drivetrain.

Compared to traditional direct-drive axles, the coaxial drive system improves efficiency. The motor power passes through a planetary gear reducer, then to the differential, the half-shafts, and finally to the wheel hubs. Automatic shifting strategies allow the motor to remain in its highest efficiency range. Regenerative braking further improves energy recovery and extends the driving range.

OEMs value the coaxial electric axle for its compactness, lightweight design, and high power density. The planetary gearbox is the core transmission structure. It is coaxial, achieves a high reduction ratio of 9 to 13 within limited space, and balances torque output. For example, GKN’s first-generation coaxial electric axle, used in the Volvo XC90, reaches a reduction ratio of 10 without a complex multi-speed gearbox. Its offset secondary reduction gear connects back to the differential, keeping all components coaxial. This efficient layout reduces space requirements and makes installation easier.

The principle of the coaxial electric drive axle differs from a conventional axle. The motor stator is fixed to the chassis. The motor shaft is a specially designed hollow shaft. The differential mounts on the motor output end cap and integrates with the hollow shaft. One axle shaft passes through the hollow motor shaft, while the other connects directly to the differential. Both shafts are coaxial with the motor output. This arrangement saves space and creates a strong, stable structure.

For commercial vehicles, the coaxial electric drive axle includes the electric drive system, rear axle assembly, vehicle frame, and universal joint. The drive system consists of the housing, motor, and planetary reducer. The housing mounts behind the rear axle and attaches to the frame using a three-point suspension. The motor and planetary reducer connect coaxially inside the housing. A universal joint connects the planetary carrier to the rear axle’s final drive input gear. This design decouples the motor from the differential, reduces vibration, and keeps the unsprung mass similar to traditional trucks.

The coaxial drive axle offers several technical and economic advantages:

✅ Compact and Space-Saving: The integrated motor and coaxial gearbox free up chassis space. This allows engineers to place the battery pack at the bottom of the vehicle without reducing cargo space. A lower center of gravity also improves stability and handling.

✅ Lightweight and Efficient: The simplified drivetrain reduces weight and increases efficiency. Compared to central direct-drive axles, energy recovery improves by up to 50% due to balanced gear operation.

✅ High Torque Density: Peak torque delivery reaches 200 Nm for light-duty versions and can scale much higher for heavy commercial vehicles. Torque density supports demanding applications like light trucks and micro urban buses.

✅ Improved Driving Comfort: Low noise and vibration technology improve ride quality, enhancing the passenger and driver experience.

✅ Low Maintenance: The main reducer requires oil changes only every 100,000 km. Optional maintenance-free wheel ends further reduce downtime and lower life-cycle cost.

✅ Safety and Reliability: Millions of test cycles validate high load capacity and structural reliability. Regenerative braking and traction control improve performance on slippery roads.

Typical specifications of a coaxial electric drive axle include:

This technology fits a wide range of vehicles: 5–6 meter pure electric city buses, urban light logistics trucks, microvans, light trucks, and pickup trucks. With scalable designs, Brogen has developed multiple versions of coaxial electric drive axles based on different axle load ratings.

| Model | OEEP6 | OEEP8 | OEEP13 |

| Axle load | 3500 kg | 5500-6000 kg | 8500 kg |

| Voltage | 540 VDC | 540 VDC | 540 VDC |

| Motor power | 135 kw/60 kw | 150 kw/90 kw | 150 kw/80 kw |

| Max. vehicle speed | 100km/h@0.372m | 85km/h@0.372m | 79km/h@0.421m |

| Maximum Gradeability | 20%@20km/h@6T | 20%@20km/h@9T | 20%@20km/h@13.5T |

| Application | For 5-6 meter pure electric micro-circulation city buses For 4.5-ton GVW urban logistics electric light trucks For 6-7.2 meter low-entry, short rear overhang, long wheelbase city buses/highway coaches | For 6-7.2 meter low-entry, short rear overhang, long wheelbase city buses/highway coaches | For 8-9 meter low-entry, short rear overhang, long wheelbase city buses. |

The Coaxial Electric Drive Axle represents a clear path forward for pure electric commercial vehicles. Its compact structure, high efficiency, energy recovery, and low maintenance cost make it ideal for OEMs and fleet operators. As cities demand cleaner and more efficient transportation, the coaxial electric drive axle will play an important role in shaping the next generation of light commercial EVs.

Brogen is a leading ev solutions provider for commercial vehicles and boats. Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube. Find more about Brogen's ev solutions for commercial vehicles.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Company Profile