Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

Permanent Magnet Synchronous Motor vs Asynchronous motor is an important topic in electrical engineering. Both motors serve as mainstream technologies, each with unique structures, operating principles, and application areas.

Permanent magnet synchronous motors (PMSM) deliver high efficiency, strong dynamic response, and compact design, making them suitable for modern industries and electric vehicle drivetrain systems. Asynchronous motors, especially induction motors and excitation synchronous motors, continue to dominate heavy-duty applications due to their robustness, lower cost, and mature production process. This article explains the differences between these two types of motors in structure, principle, performance, cost, and application.

✅ Permanent Magnet Synchronous Motor (PMSM)

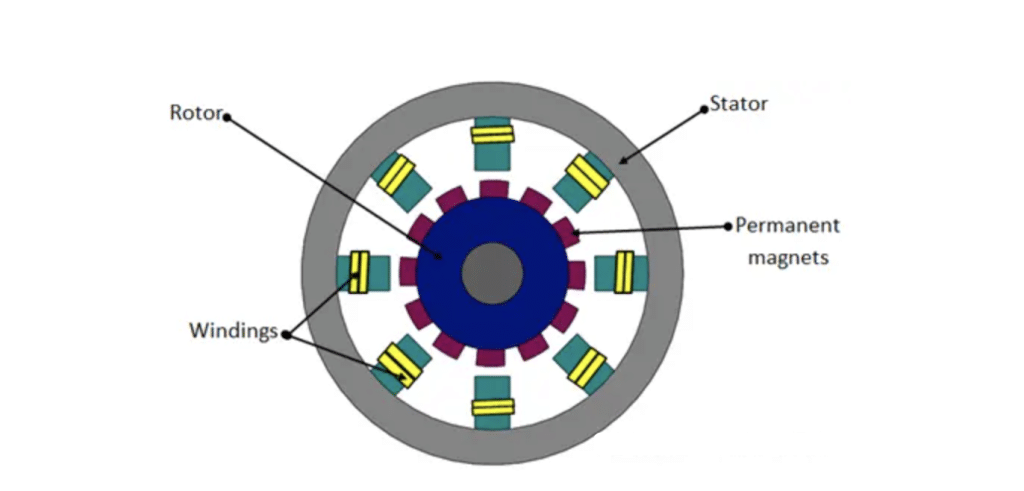

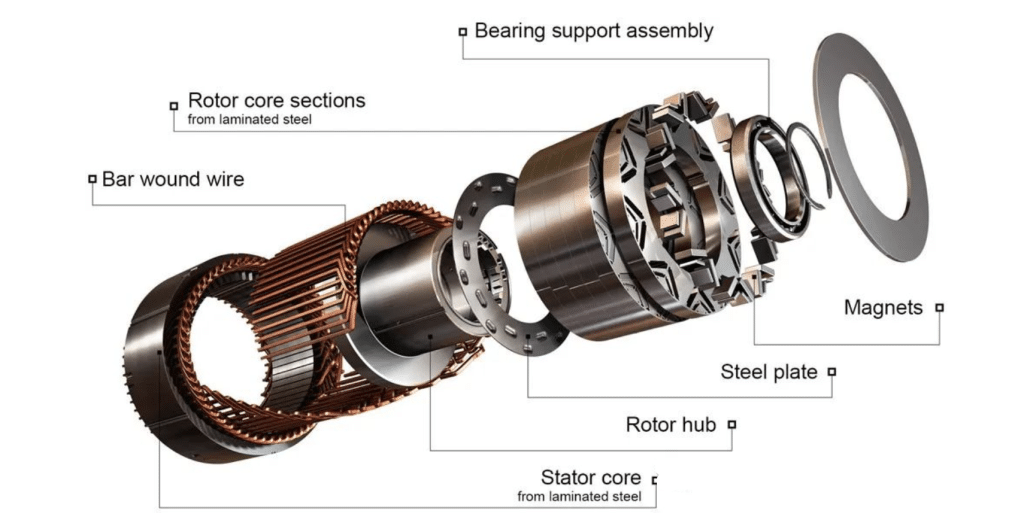

A permanent magnet motor mainly includes a motor controller, stator, and rotor. The rotor contains high-performance permanent magnet materials such as neodymium-iron-boron or samarium-cobalt. These materials provide high magnetic strength and stability without external excitation. This eliminates the need for additional excitation circuits, reduces copper and iron losses, and increases power density. PMSMs are compact, lightweight, and suitable for applications with strict space or weight limits.

✅ Asynchronous motor

Asynchronous motors, such as induction motors and synchronous excitation motors, consist of stator, rotor, bearings, end covers, and an excitation system when required. The stator has laminated silicon steel cores with embedded windings. Once current flows through, the stator generates a rotating magnetic field. Induction motors use squirrel-cage or wound rotors and rely on electromagnetic induction to create torque. Synchronous excitation motors require DC excitation through brushes and slip rings. Their structure is more traditional but mature, enabling standardized mass production.

The working principle of a permanent magnet synchronous motor depends on the interaction between the permanent magnetic field of the rotor and the electromagnetic field from the stator. In a DC PMSM, brushes and commutators provide current to the stator windings, creating torque through the interaction with the rotor magnets. In an AC PMSM, the stator produces a rotating magnetic field that pulls the rotor into strict synchronism. Because the permanent magnet provides a stable magnetic field without extra energy, efficiency and response improve significantly.

Asynchronous motors work mainly on electromagnetic induction. In an induction motor, the stator produces a rotating magnetic field that induces current in the rotor, generating torque. The rotor speed is slightly lower than synchronous speed due to slip. In excitation synchronous motors, an external DC current excites the rotor field. The motor runs synchronously with the stator’s magnetic field. Excitation control can adjust reactive power and stabilize the grid, but losses are higher compared to PMSMs.

✅ Efficiency and Energy Saving

PMSMs operate without excitation current, which lowers no-load losses and raises efficiency. They often achieve 20%–40% energy savings, especially at partial load and low-speed conditions. Asynchronous motors consume more power due to excitation loss, copper loss, and iron loss, but remain effective in large continuous power applications.

✅ Dynamic Response

PMSMs provide high starting torque, fast response, and strong overload capacity. Their torque density makes them ideal for precise control, as in servo drives and electric vehicle propulsion. Asynchronous motors show slower response and lower torque density. However, synchronous excitation motors can adjust excitation current to support grid stability and reactive power regulation.

✅ Maintenance and Lifetime

PMSMs require less maintenance. Their simple design has no brushes or excitation windings, reducing fault rate and extending lifetime. But permanent magnets may face demagnetization under high temperature, vibration, or reverse field conditions. Asynchronous motors with brushes or slip rings require more frequent service, yet their tolerance to harsh conditions and resistance to demagnetization remain strong advantages.

✅ Manufacturing Cost

PMSMs use expensive rare-earth materials, raising initial costs. Their advanced design and manufacturing add to the expense. However, as technology improves and resources expand, PMSM costs continue to fall. Asynchronous motors use widely available materials and established processes, resulting in low production cost and continued dominance in cost-sensitive markets.

Permanent Magnet Synchronous Motors excel in sectors that demand high efficiency, compact size, and fast dynamics. They appear in electric vehicles, wind power systems, CNC machine tools, robotics, and household appliances.

Asynchronous motors are widely used in heavy industry. Induction and excitation motors are used in pumps, fans, compressors, heavy machinery, auxiliary equipment in power plants, and traction systems. They handle steady-state, high-power operations effectively.

The comparison of Permanent Magnet Synchronous Motor vs Asynchronous motor shows clear distinctions. PMSMs lead in efficiency, power density, and precision control. They align with trends in green energy, lightweight design, and smart manufacturing. Asynchronous motors, on the other hand, remain reliable, affordable, and adaptable to challenging environments.

Brogen is a leading ev solutions provider for commercial vehicles and boats. Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube. Find more about Brogen's ev solutions for commercial vehicles.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Company Profile