Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

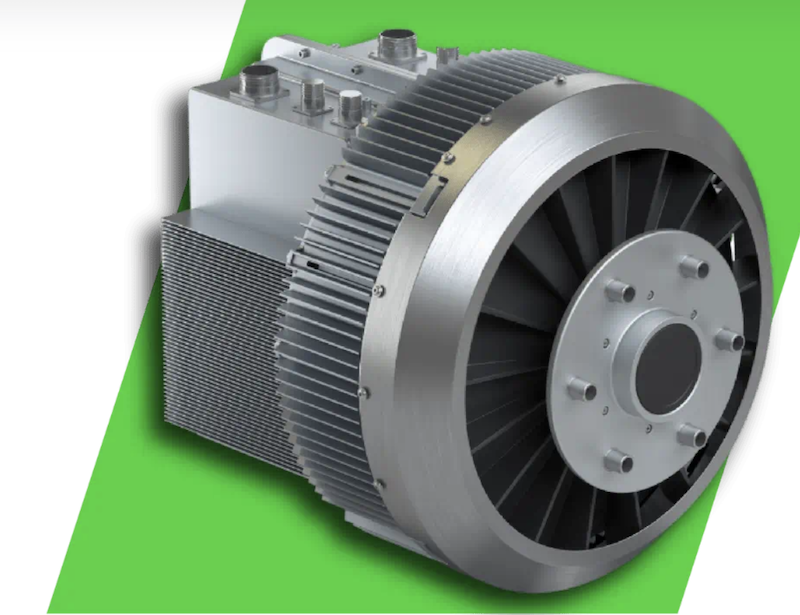

Axial flux motors are finding their place not just in electric vehicles but also in robotics, aerospace, marine propulsion, and autonomous vehicles. This piece will focus on their role in robotics.

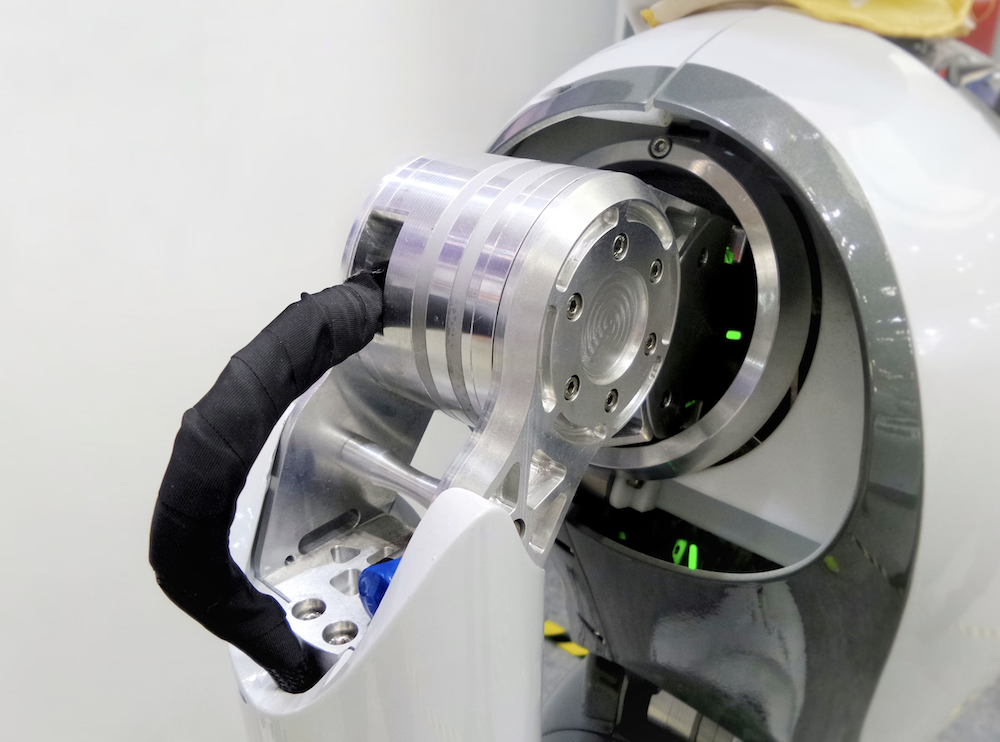

For humanoid robots, joints must be lightweight, compact, and powerful. Axial flux motors, with their compact design and high torque density, fit these needs better than traditional servo motors. As manufacturing techniques advance, axial flux motors are poised to make humanoid robots even lighter.

Robots driven by motors rely on motor controllers to manage direction, speed, and motion in various modes. These motor-driven robots offer quick response times, easy maintenance, precision in movement control, energy efficiency, and faster market adoption, making them the leading technology trend.

Image source: Unsplash

Speed: Motors should execute commands swiftly after receiving signal inputs.

High starting torque-to-inertia ratio: Joint motors need significant starting torque and low inertia under load.

Compact design: To fit into tight spaces and handle loads effectively.

Durability: Able to handle frequent starts, stops, and overloads temporarily.

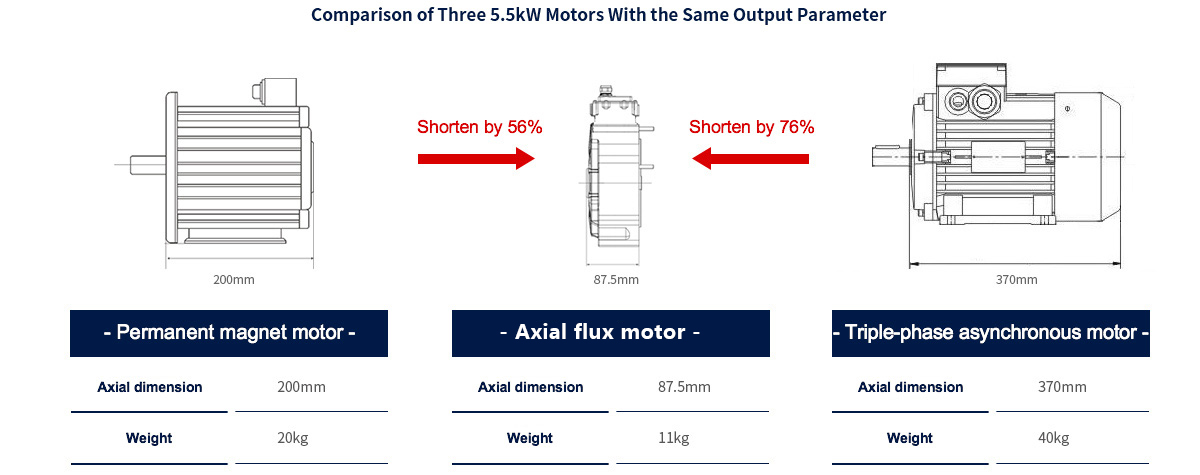

Axial flux motors excel over radial flux motors in these areas. They offer higher power and torque density, with a smaller and lighter footprint. Their shorter axial length not only contributes to lighter and more compact robot designs but also extends battery life and reduces energy use. Additionally, axial flux motors deliver more torque at lower speeds, providing greater thrust and faster response times.

Axial flux motors are being integrated into numerous robot projects worldwide.

SEMOTOR, a Chinese company, has applied axial flux motors to its exoskeleton robot. On flat roads, the exoskeleton robot moves forward by rolling on the drive wheels, with the two small wheels in front acting as support wheels. When encountering stairs, the two front wheels are retracted to turn the robot into a bipedal robot and start climbing the stairs. This robot can adapt to road environments with stairs, bringing more convenience to people with limited mobility and those who need to carry heavy loads.

Image source: SEMOTOR

Genesis Robotics, for example, has reduced ground impact on joints by leveraging the thin profile (2cm) of axial flux motors.

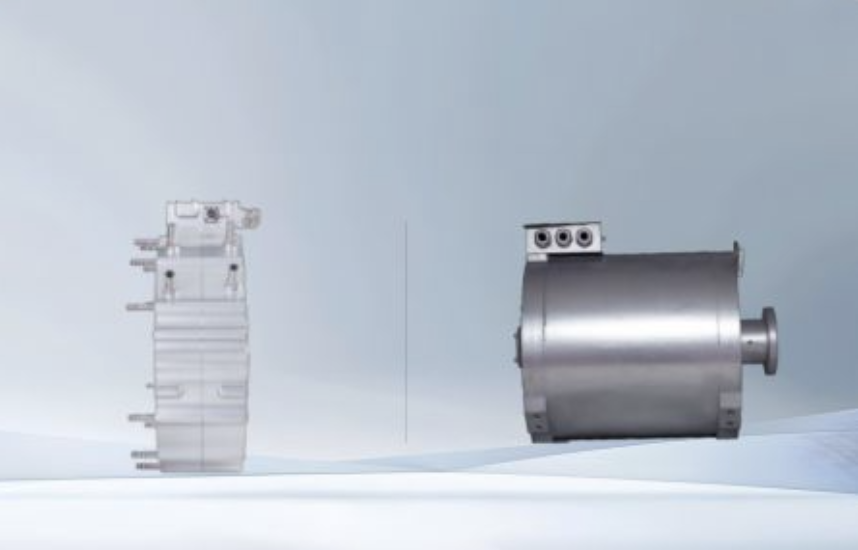

In service robotics, Japan's NIDEC DRIVE TECHNOLOGY employs a 21mm thick motor with a high output of 170W to provide the necessary starting force for joint assistance, preventing user injury from large joint movements in tight spaces.

Image source: Nidec

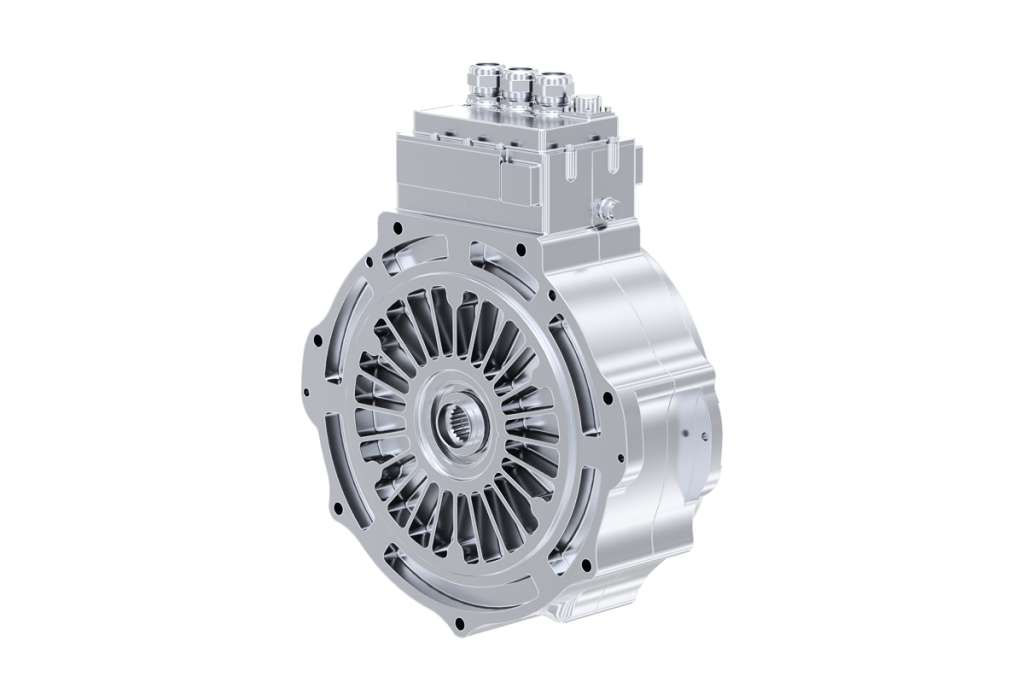

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Company Profile