Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

Electric trailer drive systems are in high demand across the logistics sector. Brogen Motors provides a complete electric trailer drive solution, compatible with both pure electric and hybrid tractors. Our hybrid trailer solution enhances fleet efficiency, cutting fuel costs and reducing emissions in heavy-duty transport.

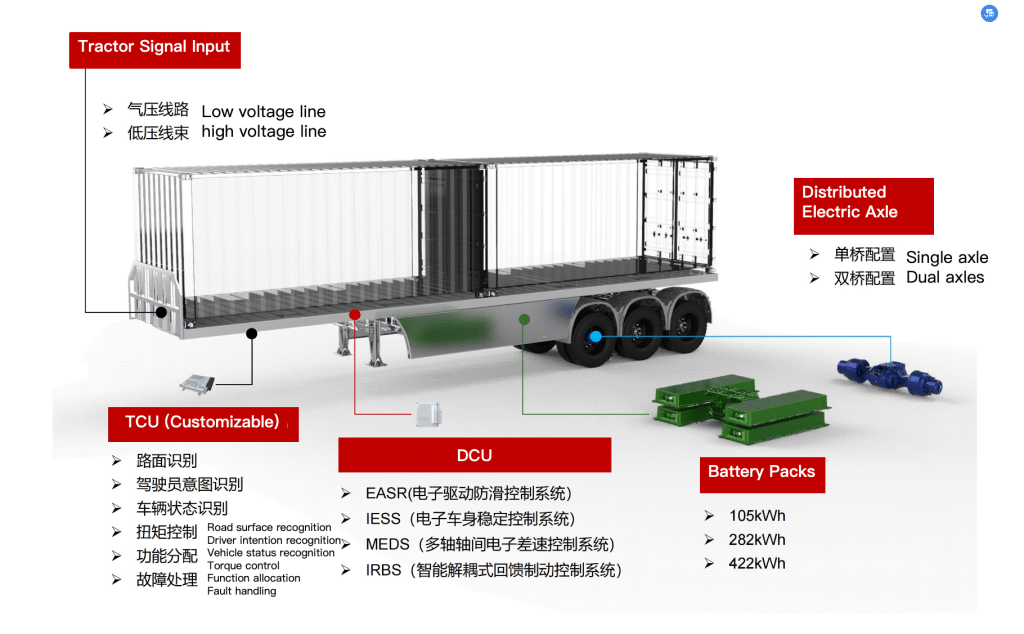

Power Supplement: Acceleration, climbing and other auxiliary power

Intelligent recovery: full decoupling of electric braking and traditional braking

Retarder function: instead of retarder, and possible energy recovery

Power Mode: Optimal Power and Torque Adaptation Control

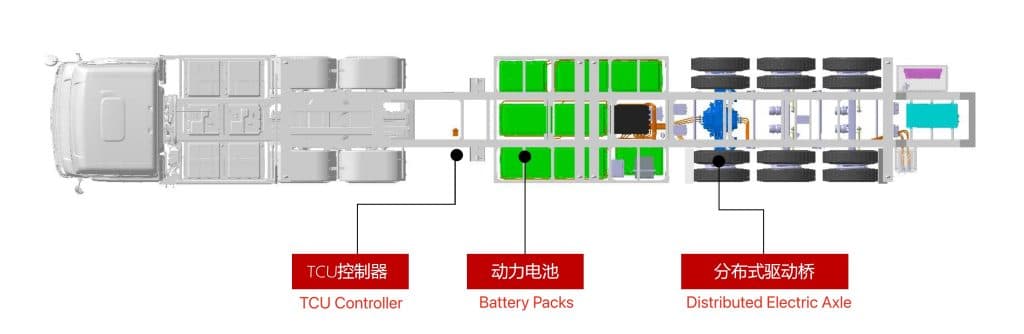

Equipped with Electric distributed drive and brake-by-wire system

Automatically detects road conditions, trailer status, and driving intentions to ensure precise control of the train.

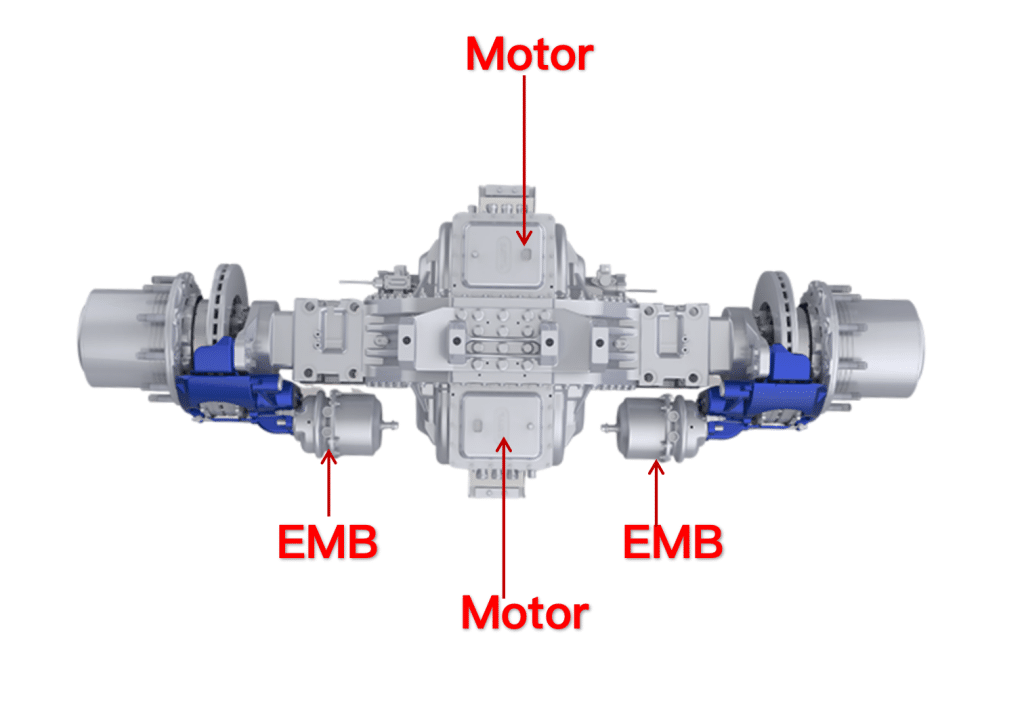

Utilizes a dual-motor distributed drive solution with electronic differential technology, enabling independent control of each tire.

Delivers a maximum single-axle output torque of 50,000 Nm and an output power of 360 kW.

Reduces installation complexity, offers fast response, precise control, and deep decoupling of drive and brake systems, enhancing overall safety.

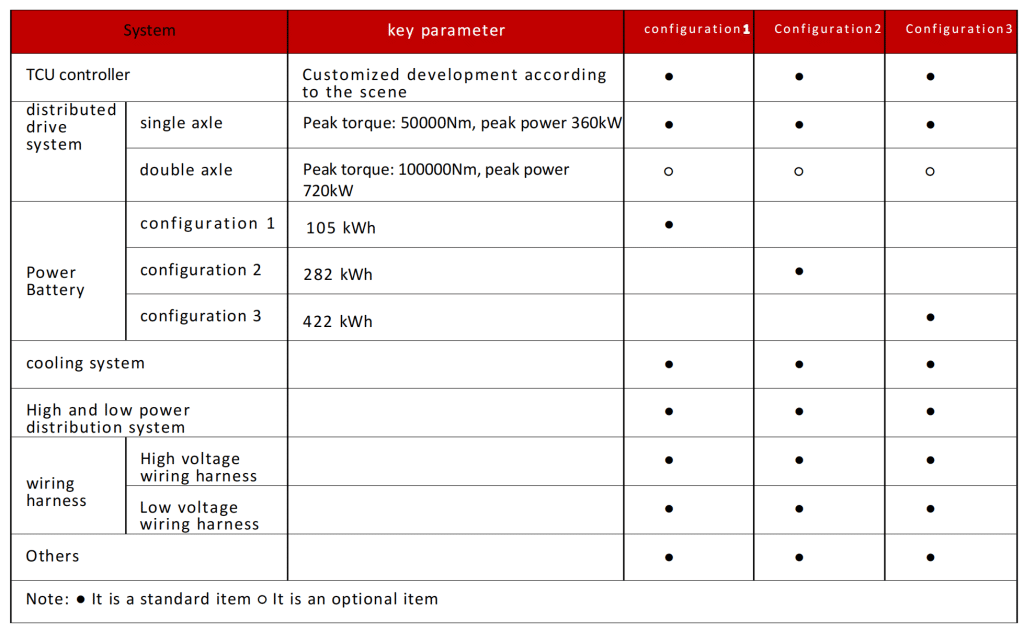

Adaptability Our system can be customized and developed based on the power and mileage requirements of the train, allowing for flexible configurations. The adaptive control algorithm is compatible with any energy source used by the main vehicle, including traditional fuel engines, pure electric systems, and hydrogen fuel cells.

Safety The distributed active control system enables electronic drive anti-skid (EASR) and body stability control (IESS), enhancing trailer stability and preventing tail-swinging. Optional Electromechanical Braking (EMB) provides faster braking response and deep decoupling from pneumatic brakes, further improving the safety and efficiency of the entire vehicle.

Environmental Protection The intelligent drive trailer system delivers electric drive power, maximizes the engine’s high-efficiency zone, and recovers energy during deceleration. This significantly reduces carbon emissions for traditional fuel vehicles.

Energy Efficiency The system increases running speed and operational efficiency while improving road adhesion utilization, which reduces tire wear.

Ideal for short-distance, heavy-load, and steep-climbing scenarios, effectively addressing power and mileage challenges.

Example: A 49T traditional fuel vehicle consumes 31.9L of fuel per 100km round trip. Operating twice daily for 300 days a year, each vehicle emits 191.2T of carbon annually.

Based on calculations for transporting a single container, the purchase price of an electric vehicle is estimated to be ¥506,000 higher than that of a diesel vehicle. However, it can save approximately ¥275,000 in annual operating costs, allowing for cost recovery in about 1.84 years.

If the electric vehicle is used to transport two containers, its purchase price would be approximately ¥360,000 higher than the cost of two diesel vehicles, but it could save ¥916,000 annually in operating expenses and an additional ¥200,000 in driver wages, resulting in an estimated payback period of just 0.32 years.

Hybrid power is well-suited for mountainous and hilly terrains, achieving a fuel-saving rate of over 20% in demanding conditions such as mining and industrial areas.

For Example: With a one-way full load distance of 110 km, the engine achieves a fuel saving rate of 31.2%. Each vehicle completes two trips per day, operating 300 days per year, resulting in an annual carbon emission reduction of approximately 43.8 tons per vehicle. Based on the cost of transporting a single container, the purchase price of an electric vehicle is estimated to be ¥177,000 higher than that of a fuel vehicle, but it can save around ¥101,000 in annual operating costs, allowing for cost recovery in approximately 1.75 years.

Are you interested in empowering your EV project? Contact us at inquiry@brogenmotors.com. For more electric powertrain solutions please click EV Powertrain. For more videos please click Brogen’s Youtube. For the latest news please view Brogen’s Linkedin. Please note that our products are not ready-made or plug-and-play type. Depending on customers' different requirements, it may involves many customizations and modifications. For further discussion please contact us.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual