Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

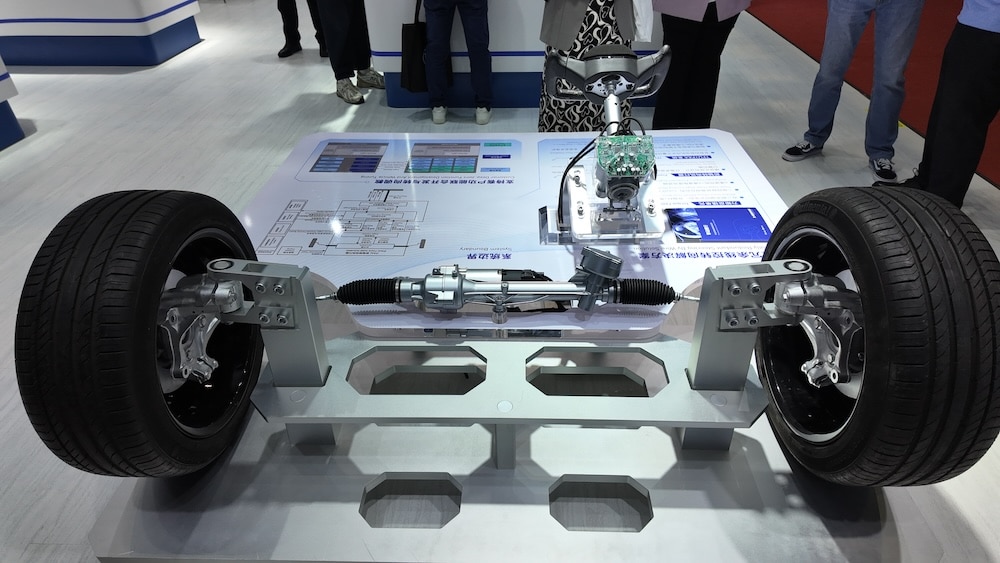

Wire-Controlled Chassis technology dominated the spotlight at the 2025 Shanghai Auto Show, cementing the event as a global barometer for automotive innovation. This revolutionary advancement signals an industry-wide shift toward drive-by-wire architectures.

This key technology is quickly transitioning from the laboratory to mass production. Its development speed far surpasses industry expectations. Compared with previous exhibitions, a significant change is evident. Wire - controlled technology is no longer just a technical demonstration at parts suppliers' booths. Instead, it appears in the core exhibition areas of big OEMs as a complete system, indicating that the technology has entered the commercialization countdown.

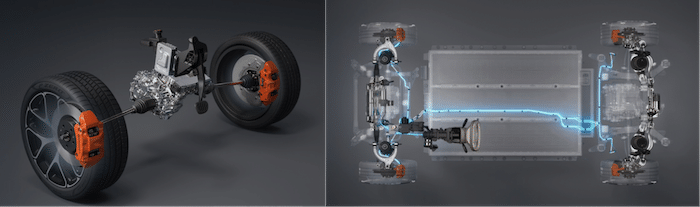

At the exhibition, SAIC Zhiji Auto's third - generation wire - controlled digital chassis technology drew wide attention.

This technology's most remarkable feature is its breakthrough in space utilization efficiency. It enables the nearly 5 - meter - long L6 to achieve a 4.69 - meter turning radius, comparable to that of a small car. This achievement comes from over a decade of continuous research and development. Its core lies in the innovative digital collaborative control of six degrees of freedom across the X/Y/Z axes. Notably, its dual - redundant dry - wire brake system stands out. Measured data shows that its response speed is 200 - 300% faster than traditional hydraulic systems, and the braking distance shortens by 6 - 8%. This means it can effectively prevent collision accidents in emergencies.

SAIC Zhiji has adopted a steady technology evolution route. Its "four - step" strategy clearly outlines the path of technological breakthroughs from local to overall: In 2024, it will realize the basic version of 6 - degree - of - freedom control; in 2025, it will mass - produce single - wheel braking and large - angle rear - wheel steering; in 2026, it will launch the front - and - rear pure wire - controlled steering system; and finally, in 2027, it will achieve the full - stack wire - controlled Linglizard digital chassis. This step - by - step development model ensures technical reliability while maintaining market appeal.

In contrast, the BYD Z concept car presents a more radical innovation concept. As the first chinese sports car equipped with a fully self - developed wire - controlled steering system, it completely abandons the traditional steering column structure and uses a fully embedded folding steering wheel design. This innovation not only eliminates the risk of steering column intrusion but also frees up 14% more space in the main driving area. Even more striking is its Yunnian - M intelligent magnetorheological body control system.

Based on advanced magnetorheological principles, the system can achieve two - way stepless adjustment of rebound and compression, with a damping response time of less than 10 milliseconds. Coupled with the preview system, it can intelligently adapt to various complex road conditions, truly achieving the driving experience of "stable as a rock in sharp turns and smooth as walking on flat ground."

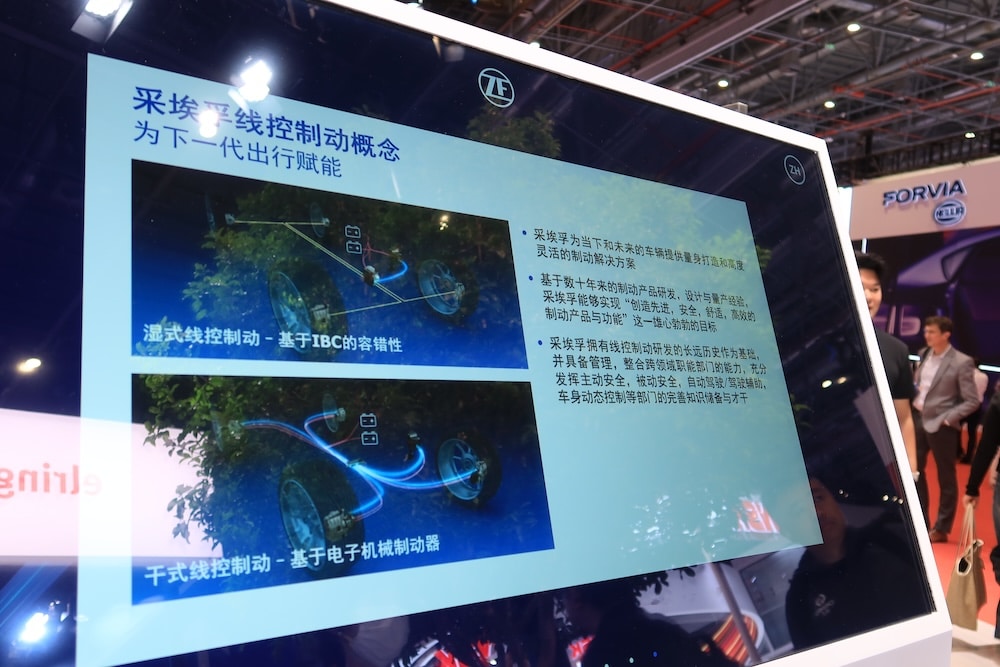

Multinational automotive parts giants also showcased their technical strengths at this auto show.

Bosch employs a "dual - track parallel" strategy. On one hand, it continues to advance the research and development of the full dry EMB system. On the other hand, it optimizes the existing hydraulic wire - control solution. Its latest BWA + ESP®10 system has been selected by chinese mainstream original equipment manufacturers (OEMs) and is expected to enter production in the fourth quarter of 2025. More importantly, the cross - domain vehicle motion intelligent control system it developed deeply integrates subsystems like braking, steering, and suspension through software algorithms. This provides reliable execution redundancy for high - level autonomous driving.

ZF brought a complete "Chassis 2.0" solution, and its wire - controlled steering system was first installed in the NIO ET9. Notably, its sMOTION® fully active suspension technology can adjust in real - time according to road conditions. It also innovatively integrates entertainment functions, such as the "4D Cinema" mode developed for Porsche models. ZF announced that the technology will be localized in Chinese factories in 2026.

Continental has chosen a differentiated technology path. Its newly developed integrated wire - controlled brake system features a highly compact design, reducing the system's total weight by nearly 30%. In the long run, the company is developing an electric caliper system that requires no brake fluid, which will significantly cut maintenance costs and enhance environmental performance.

China's intelligent chassis industry is achieving three major breakthroughs:

Technology research and development has shifted from following to running alongside international giants, competing in cutting - edge fields like wire - controlled steering and EMB.

The industry chain has become independent and controllable, with chinese chip solutions and independent software architectures building a technological barrier.

Ecological synergy effects are obvious, and standardized interfaces have accelerated the deep integration of intelligent chassis and vehicle domain control.

This chassis revolution driven by wire - controlled technology is more significant than mere car performance improvement. It is reconstructing the entire automotive industry's value chain. On one hand, the technical barriers of traditional mechanical transmission have been broken, and a new industrial pattern is emerging. On the other hand, the trend of software - defined chassis has led to the reshaping of automotive development models and supply chain relationships.

With the approach of the mass production milestone in 2025, this transformation has entered a crucial stage. Whoever can gain the upper hand in this round of technological competition will hold a leading position in the future development of intelligent connected vehicles.

If you need to electrify your engineering fleet, please contact us. We will provide a suitable solution for you. Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

Brogen is a leading ev solutions provider for commercial vehicles. You can find more ev solutions in our website, for example, electric vehicle powertrain solution, battery solution, and electric axle systems. Beside that, we have the cutting-edge axial flux motors for Automakers, who pursue excellent engine performance. We are proud to serve as your one-stop solution for navigating the rapidly expanding electric vehicle (EV) market.

For more videos please click Brogen’s Youtube. For the latest news please view Brogen’s Linkedin. Please note that our products are not ready-made or plug-and-play type. Depending on customers' different requirements, it may involves many customizations and modifications.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual