Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

Drive motor loss control and thermal management are two critical aspects in the design and operation of electric drive systems. As electric vehicles, mining trucks, and industrial automation continue to grow, drive motors face increasing demands for higher efficiency, power density, and operational reliability. The performance of a drive motor directly impacts the system's energy efficiency, continuous power capability, and lifespan. This article provides an in-depth explanation of the main technologies for minimizing motor losses and enhancing thermal management.

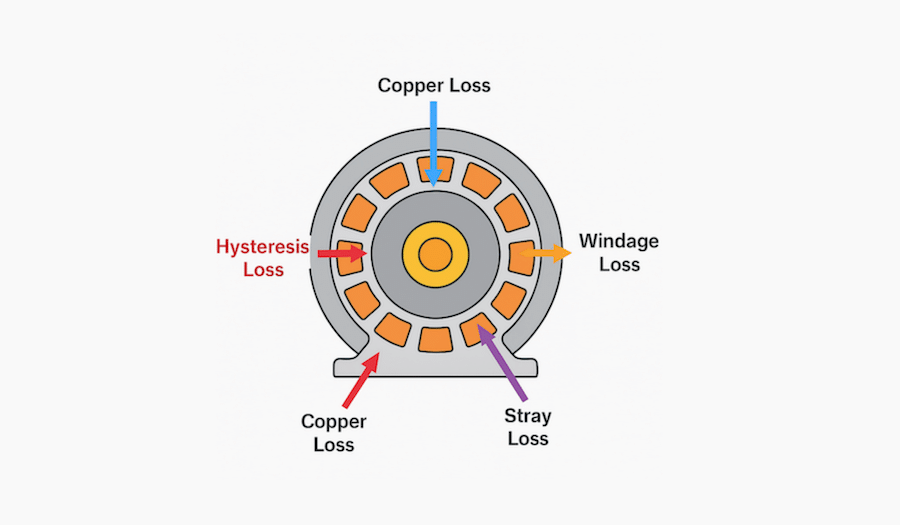

Drive motors generate various types of losses during operation. These include electromagnetic losses, copper losses, stray losses, and mechanical friction (windage). Minimizing these losses is essential to improve energy efficiency and reduce internal heating.

The electromagnetic design is the foundation of a high-efficiency drive motor. Optimizing the magnetic circuit and structural geometry helps reduce unnecessary energy conversion losses.

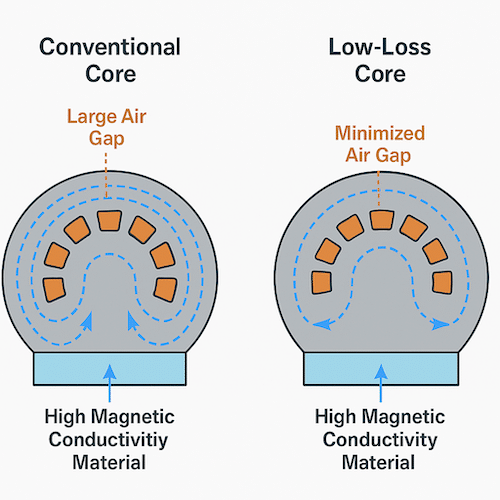

Core material selection: Using low-loss and high-permeability silicon steel can reduce hysteresis and eddy current losses;

Slot and air gap design: Optimized dimensions improve magnetic field utilization and minimize leakage flux;

Sine-wave winding: Adopting Y-Δ winding topology improves field uniformity and operational stability;

Precision manufacturing: High-accuracy assembly minimizes magnetic field distortion and structural mismatch.

Copper loss is caused by electrical resistance in the windings. It is especially critical in high-power applications such as electric mining trucks or heavy-duty industrial motors.

Rectangular conductor windings: These improve slot fill factor, reduce voids, and increase current capacity;

Increased copper area: Thicker wires and more turns help lower resistance;

Compact winding layout: Reduces parasitic inductance and heat generation during high-frequency operation.

Stray losses come from non-ideal magnetic paths and eddy currents in motor components. They can be mitigated through structural and magnetic optimization.

End region structure improvements: Minimize stray magnetic flux paths;

Magnetic shielding: Use of magnetic rings or isolation sheets to control unwanted flux;

Advanced simulation and testing: Identify hidden loss zones and optimize accordingly.

Mechanical losses, including windage and bearing friction, become significant at high speeds.

Optimized bearing design: High-efficiency lubrication and high-rigidity bearing structures reduce mechanical resistance;

Aerodynamic casing design: Reduces air resistance around the rotor and stator;

Dynamic balancing: Minimizes vibration and unwanted rotational load.

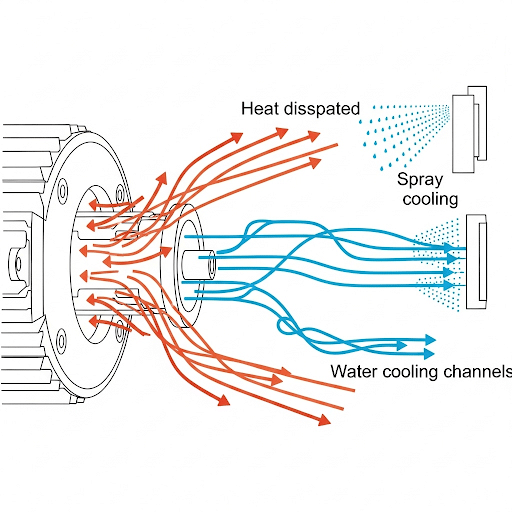

Efficient thermal management ensures the motor can operate continuously under heavy loads without performance degradation. It also extends the motor’s operational life and improves safety.

Direct liquid spray onto winding ends is an effective method to remove heat from the motor’s hot spots.

High local cooling efficiency: Spray cooling at the end windings can achieve up to 68% cooling effectiveness;

Increased power and torque density: Allows higher current flow and better thermal limits;

Improved conductivity: In motors with high slot fill, thermal conduction increases by up to 150%;

Coolant options: Water-glycol or oil mixtures are commonly used in closed-loop systems.

A water-cooled shell provides an external heat dissipation path. This method is widely used in mid-to-high-power motors.

Common structures: Include circular, spiral, and axial water channels;

Circular water jackets: Balance cost and performance, making them the preferred industry choice;

Example: Tesla Model S: Uses a labyrinth-style water channel for both stator and rotor cooling, combining axial and circular flow for optimal results.

Oil cooling allows more direct heat removal from internal components and is suitable for heavy-duty, long-duration operation.

Internal oil spray: Enhances continuous power capability by up to 50%;

Design challenges: Oil distribution is affected by centrifugal force and complex winding geometries;

Solutions: Include optimized spray nozzles, guided flow channels, and CFD-based thermal simulations.

For extreme performance needs, some motors use combined cooling strategies. Dual-path cooling: Oil spray at the end winding combined with water jacket around the casing;

Redundant heat paths: Increase reliability in critical applications;

Optimized fluids: Use glycol-water mixes and dedicated lubricating oils.

Thermal resin is applied to stator windings to fill air gaps and improve thermal conductivity.

Conductivity improvement: Thermal epoxy or silicone gel can reach 2.0 W/m·K;

Power output increase: Up to 15-20% improvement from better heat extraction;

Mechanical benefits: Reduces vibration, noise, and enhances moisture resistance;

Low-cost process: Simple application with moderate cost increase.

To achieve higher torque density and broader speed range, modern motors adopt multi-layer permanent magnet rotor structures.

Increased magnet volume: Better use of limited rotor space;

Reluctance torque improvement: Higher saliency ratio leads to more output torque;

High-speed capability: Enhanced rotor strength and reduced demagnetization risk;

Cost optimization: Reduces reliance on expensive rare-earth magnets.

The combination of loss control and advanced thermal management is essential to develop high-performance, high-reliability drive motors. These technologies are especially critical in applications such as electric mining equipment, heavy-duty trucks, and industrial machinery. By adopting optimized materials, structural innovations, and hybrid cooling strategies, manufacturers can deliver motors that meet the demands of the next generation of electric drive systems.

Brogen is a leading ev solutions provider for commercial vehicles and boats. Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube. Find more about Brogen's electric drive motors.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual