Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

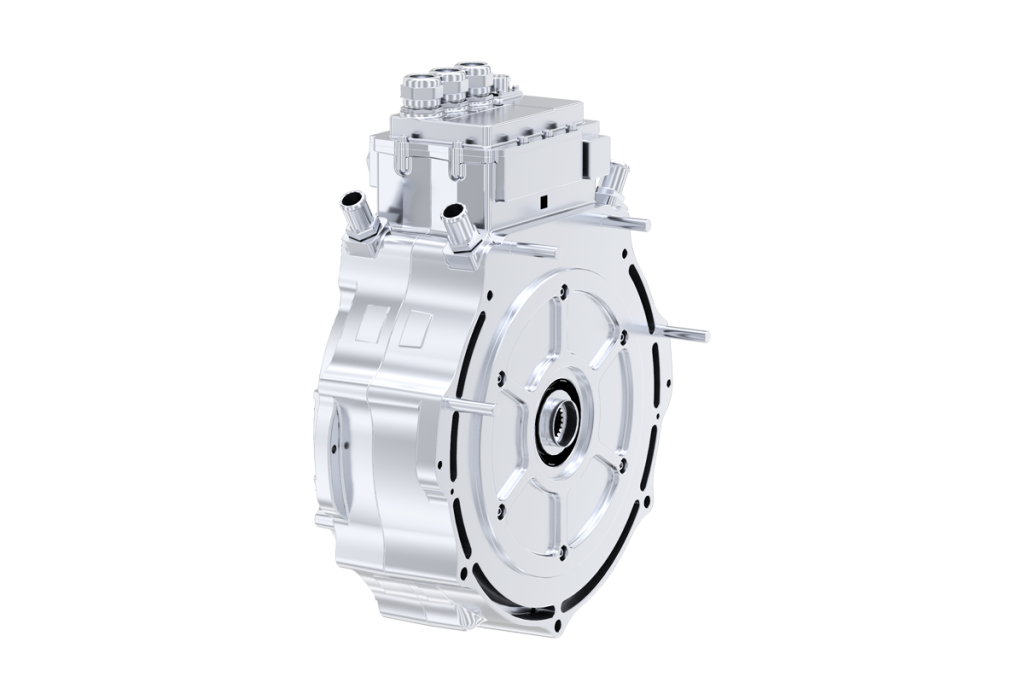

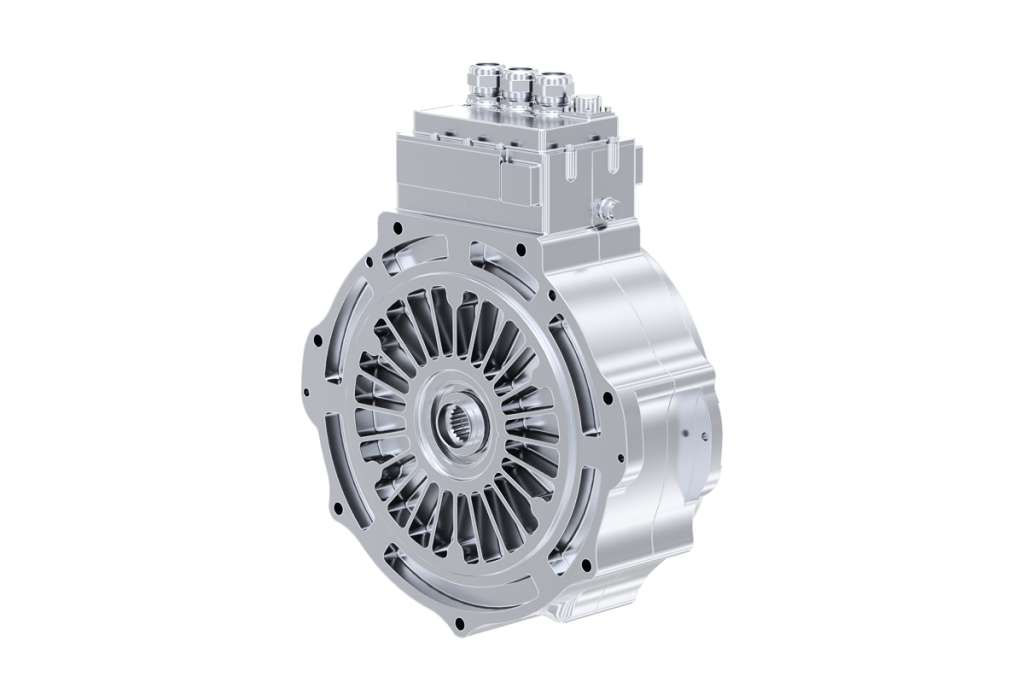

Due to the technical characteristics of axial flux motors, such as compact structure, flat and ultra-thin, small size, light weight and high-power density, many developers have worked hard to improve this technology in the past decade to have gradually suitable for new application scenarios such as electric motorcycles, airport pods, cargo trucks, electric vehicles, and even electric aircraft.

The design of a new axial flux motor typically improves the torque density by more than 30% compared with the design of a traditional radial flux motor.

The current research hotspots (i.e., technical trends) for this type of motor in the field of electric vehicles is to improve efficiency, reduce costs, system integration and NVH improvement.

The innovation of axial flux motor technology mainly lies in structural design and has essentially overcome the key technological barriers in thermal management, advanced materials and batch production processes.

Although axial flux motors have technical advantages and after years of technical research, the industry has mastered the working principle of new axial flux motors and has basically broken through the key technologies of configuration and structural design, electromagnetic performance design, thermal performance design, calibration and control strategy development.

Widespread application will take some time before it can be applied in large quantities, and a series of technical challenges in design and production need to be overcome.

Because of the lack of research accumulation, the industry has a poor understanding of the manufacturing methods of axial flux motors, manufacturing equipment is not easy to obtain, and the industrial chain is not perfect.

Axial motors must maintain a uniform air gap between the rotor and stator because the magnetic force is much higher than that of radial flux motors.

Considering that it is also difficult to adjust the air gap during motor manufacturing, it is necessary to accurately control the manufacturing tolerances of key components.

The axial flux motor adopts a sandwich structure. The intermediate stator of the dual-rotor axial flux motor and the intermediate rotor of the dual-stator axial flux motor is difficult to dissipate heat. In addition, due to the high specific power characteristics of the axial flux motor, the heat capacity is also very small, which leads to extremely serious heating problems.

It is necessary to adopt new heat dissipation methods such as immersion oil cooling, oil-water composite cooling, liquid nitrogen cooling and phase change material cooling, and design extremely complex cooling and sealing structures.

For radial flux motors, the cost of magnets, silicon steel, copper, structural parts as well as the process cost of mass production have been recognized by the industry.

However, the industry has insufficient knowledge of the new materials and new processes used in the new axial flux motor. The R&D investment cost can be reduced, but the low maturity of industrialization, high cost, and high uncertainty in cost are the biggest obstacles to the mass production of the new axial flux motor.

For example, the Swedish Koenigsegg Regera and Hongqi S9 supercars are equipped with three motors provided by YASA MOTORS, of which two YASA 750 motors are located on the left and right axles of the rear axle to directly drive the wheels, and the other YA-SA 400 motor is located at the front end of the engine and connected to the engine crankshaft to supplement the engine's power output.

On July 22, 2021, Mercedes-Benz officially announced its new electrification strategy plan.

According to the plan, Mercedes-Benz will launch three new pure electric vehicle architectures in 2025. Mercedes-Benz will cover all medium and large passenger cars and establish a scalable modular system as the backbone of the future electric product portfolio. It will be a dedicated high-performance electric vehicle platform, providing solutions for technology- and performance-oriented Mercedes-AMG models.

VAN.EA provides support for electric vans and light commercial vehicles.

At the same time, Mercedes-Benz announced the acquisition of YASA, a next-generation electric drive technology company. YASA became a wholly owned subsidiary of Mercedes-Benz and will provide electric motors for Mercedes-Benz's pure electric platform, trying to redefine future driving performance with electric motors with higher power density and continuous torque output. This is bound to push the research on new axial flux motor technology for automotive electric drives to a new level.

At Brogen, we're committed to offering custom EV solutions. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

We have delivered high-quality electric powertrain solutions to over 100 customers across more than 20 countries.

Get in Touch with Our Experts

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube.

For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual