Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

In the burgeoning sector of electric heavy trucks, DeepWay's intelligent electric tractors have garnered significant attention from industry experts due to their distinctive design and pioneering battery placement. DeepWay has swiftly made market inroads in the new energy tractor domain, deploying over 500 units within months of its 2023 launch and achieving 825 units sold in the first half of 2024, positioning itself as one of the fastest-growing companies in the electric heavy truck segment.

Image source: Deepway

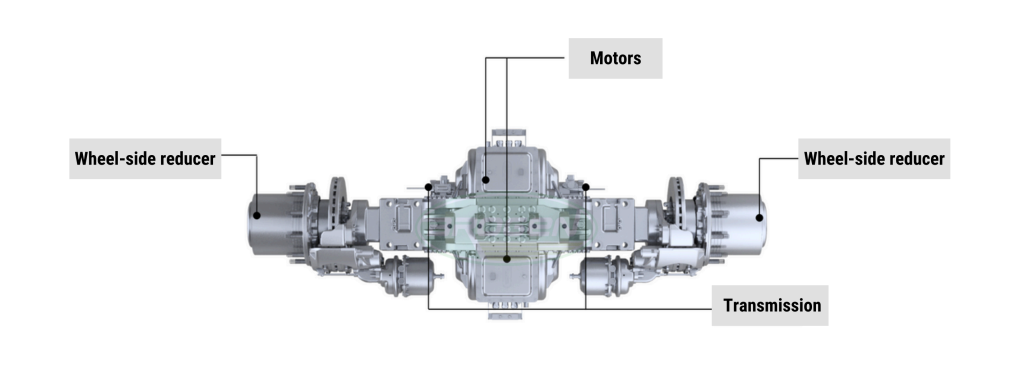

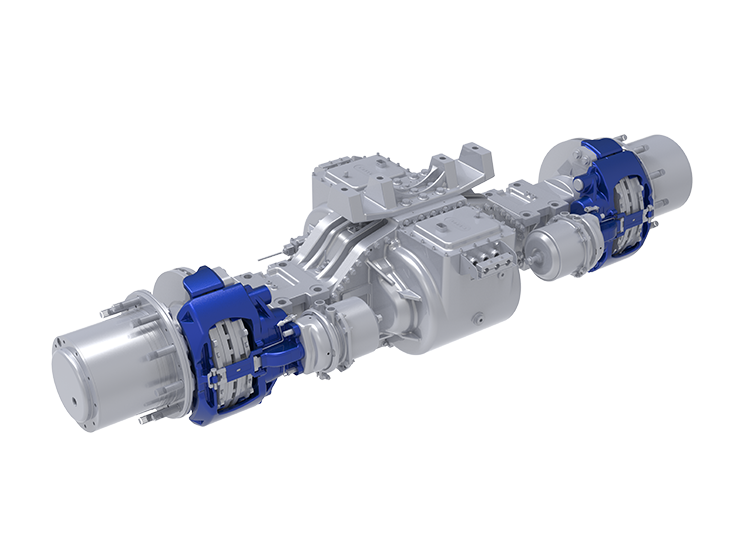

The new 6x4 battery-swap tractor from DeepWay features an advanced distributed electric drive axle system. The middle and rear axles are fitted with integrated electric drive axles, boasting a dual-motor configuration with a rated power of 224 kilowatts and a peak output of 492 kilowatts (669 horsepower). This setup delivers a peak torque of 1640 Nm, rivaling the performance of conventional fuel vehicles. The dual power architecture promises a more robust and seamless driving experience for customers.

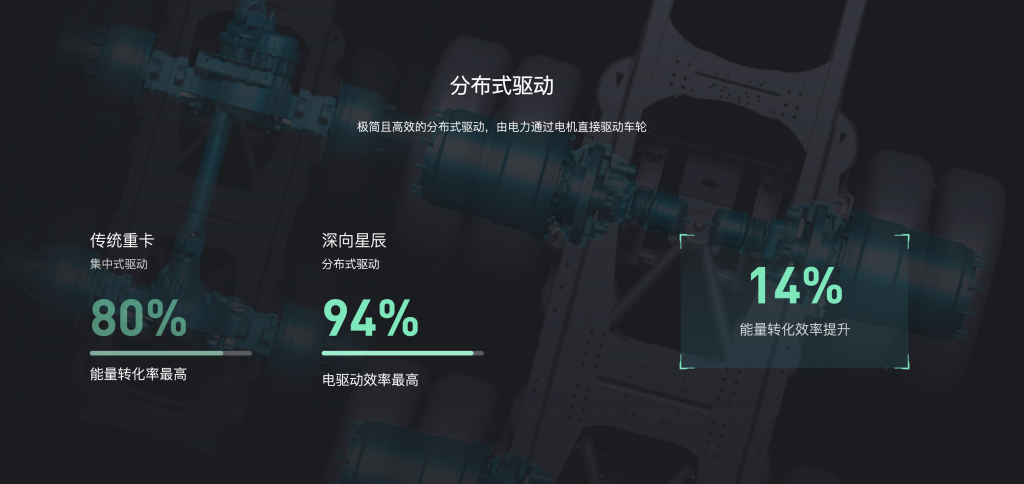

The website indicates that the distributed electric drive axle system achieves a transmission efficiency of 94%.

Image source: Deepway

DeepWay's flagship model, the Shenxiang Xingchen, is powered by a 466kWh battery pack, with cells supplied by CATL. This lightweight battery pack assembly boasts an energy density of 130Wh/kg. With a full load of 49 tons, the energy consumption is rated at 150kWh/100km, enabling a driving range of over 300km on a single charge, and more than 600km with a single battery swap. The battery, strategically placed at the chassis' base, ensures a more balanced and safer axle load distribution. The integrated charging and swapping design allows for a 6-minute battery replacement, facilitating around-the-clock high-frequency operations.

Traditionally, oil-to-electric new energy heavy trucks carry a substantial battery backpack, which significantly reduces chassis utilization and cargo space while increasing the vehicle's center of gravity, thereby limiting the range.

As stated by Wan Jun, founder and CEO of DeepWay, "Only a comprehensive forward design can fully leverage the advantages of electric drive and develop a chassis capable of supporting wire control, backup redundancy, and safety features essential for intelligent driving."

This philosophy is embodied in DeepWay's integrated charging and swapping heavy trucks. By placing the battery pack on the chassis, DeepWay significantly enhances chassis utilization, lowers the vehicle's center of gravity for improved stability, and extends the vehicle's range to meet diverse operational needs, including express delivery, bulk coal transportation, and port logistics.

Image source: Deepway

The electric drive systems in new energy vehicles are trending towards integration and compact power systems. Distributed electric drive axles offer weight reduction, volume minimization, and enhanced power and torque density.

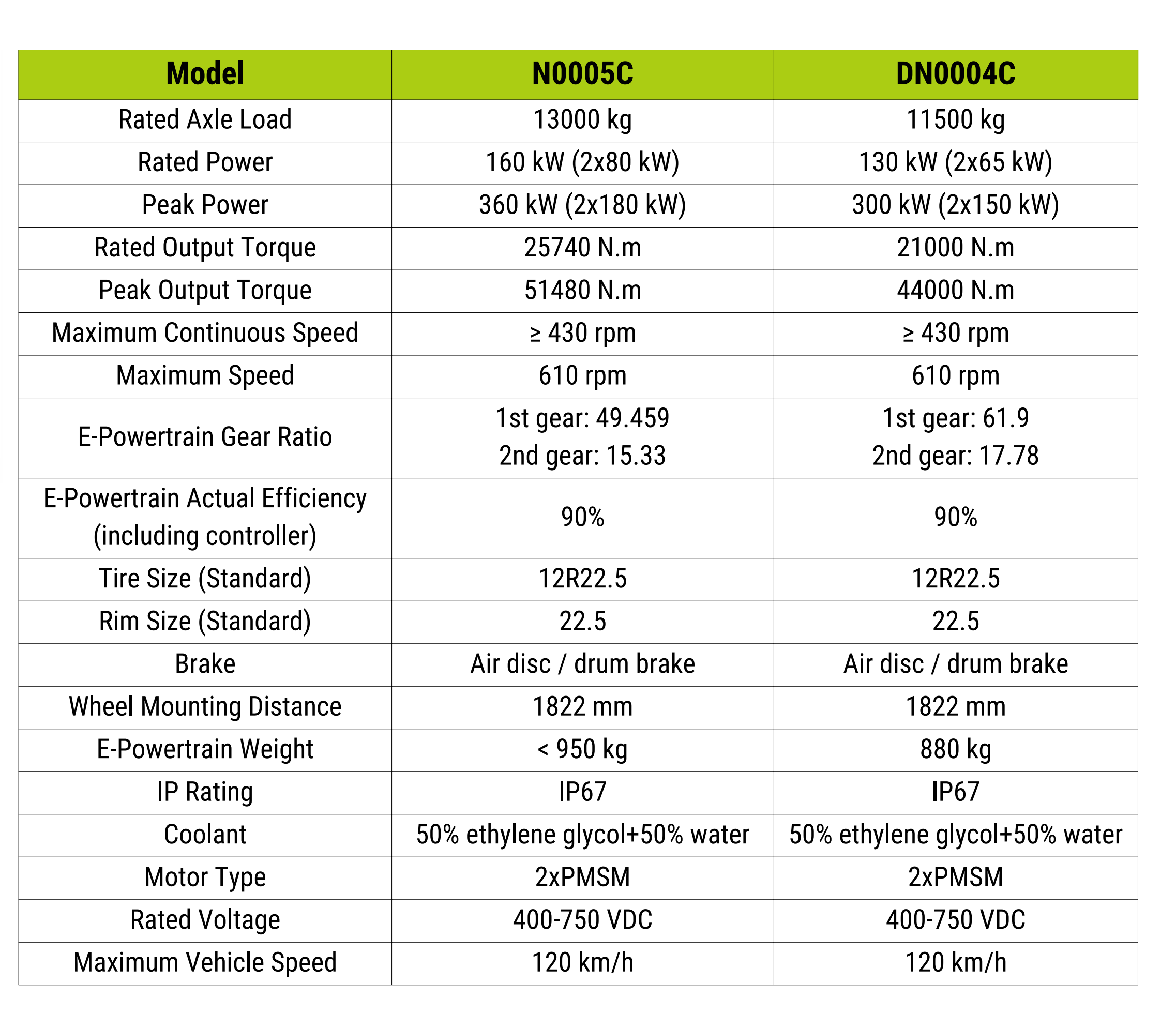

Brogen supplies variety electric axles for different kinds of vehicles including vans, buses, LDVs, HDVs, sanitation vehicles, sweepers, construction vehicles and so on . We are able to provide customizable opitions for your unique requirements.

Our distributed electric axle key features:

Dual-Motor Design: Integrating the dual motor structure and advanced gear-shifting control strategy to ensure uninterrupted power delivery during gear shifts.

Distributed Drive Approach: Adding additional safety redundancy to the vehicle, offering a flexible power distribution strategy for different working conditions.

Compact & Lightweight: The integrated design lowers the gravity center of the battery system, increasing the stability of the whole vehicle.

Advanced Core Technologies: Equipped with EDS, EASR, IESS and other safety configurations to increase vehicle safety and stability in harsh environments.

At Brogen, we're committed to offering custom EV solutions. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube. For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual