Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

Our client, a commercial vehicle manufacturer based in Turkey, has a wealth of experience in producing traditional diesel-powered buses. Driven by Turkey's environmental policies, they initiated a new project in 2022 to manufacture electric buses. We have been their supplier for steering pumps (EHPS) and brake pumps and have achieved high satisfaction in both products and services. Consequently, when they kicked off the project to electrify their buses, they sought us to provide high-quality LFP battery for buses which are 8 meters long and 12 meters long.

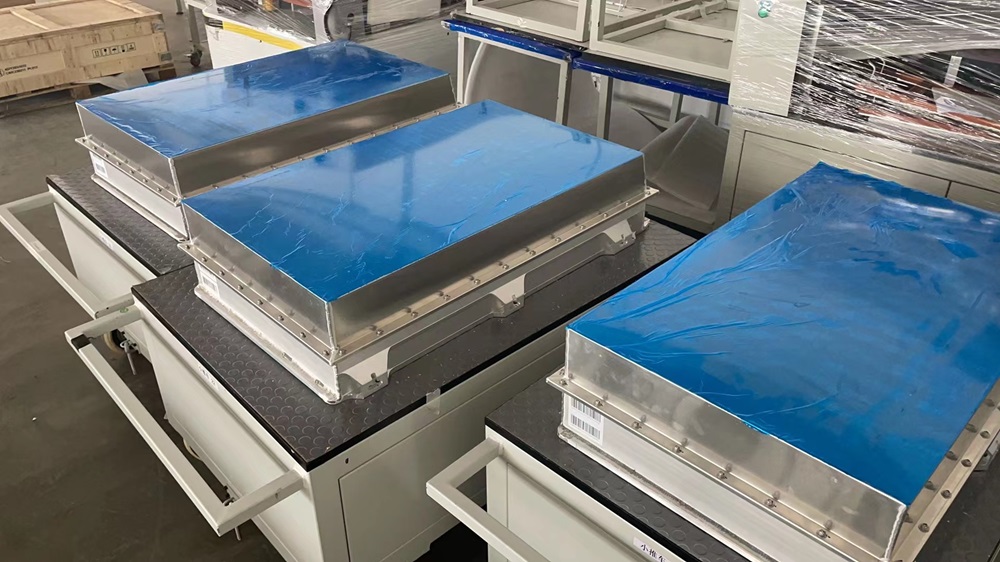

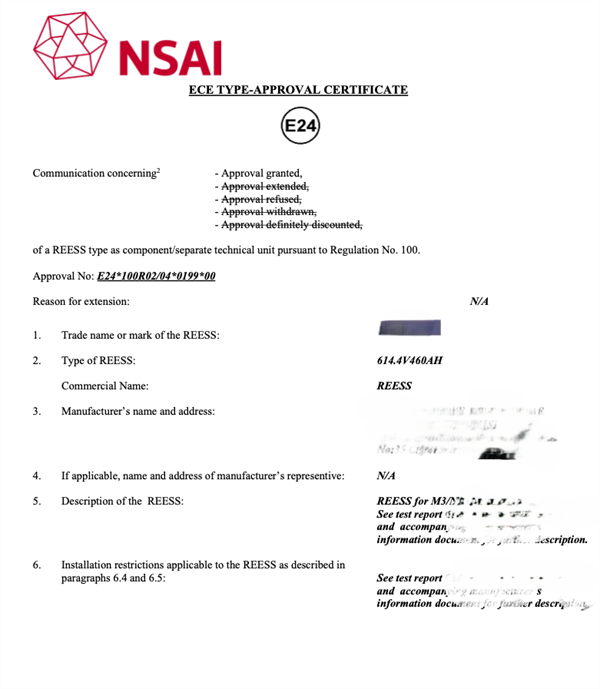

We successfully delivered seven sets of 280 kWh battery packs and developed the corresponding Battery Management System (BMS) and cooling systems. Currently, the 8-meter bus and 12-meter bus are undergoing normal testing and have obtained professional certification ECE R100 for mass production.

Oct. 2022~ Aug.2023

8-meter Bus and 12-meter Bus

| No. | Part Name | Description | Unit | Quantity |

| 1 | Battery Module | 230Ah 1P16S module | PC | 24 |

| 2 | BMS | 1 BMU + 8* M 48, and supporting communication acquisition wire harness in the box | Set | 1 |

| 3 | PDU | Inclusion BMS master + high voltage components | Set | 1 |

| 4 | Power output wiring harness | Discharge positive electrode, discharge negative electrode | Set | 2 |

| 5 | Vehicle communication wiring harness | Low voltage | Set | 1 |

| 6 | CCS Charging seat wiring harness CCS | Charging wiring harness | Set | 1 |

| 7 | Battery input harness | Battery positive electrode, battery negative electrode | Set | 4 |

| 8 | Power wire harness between the battery boxes | Set | 6 | |

| 9 | Communication wiring harness between the battery boxes | Set | 8 | |

| 10 | EVCC | Set | 1 | |

| 11 | Charge harness | Set | 1 |

The requirements of lithium high voltage battery vary depending on the length of the bus. It means our experts need to design two different solutions for the 8-meter and 12-meter buses based on their size and layout.

The electric motor of the bus has been determined to be 700V, which is not a common voltage. Normally the rated voltage of ev lithium battery are 540V and 614V. To meet the needs of the Turkish OEM, we need to configure the appropriate high-voltage lithium battery according to the motor’s rated voltage.

Based on the specific needs of each bus model, we design battery packs of different capacities. For example, an 8-meter bus might require a smaller battery pack to accommodate its smaller passenger capacity and weight, while a 12-meter bus might need a larger battery pack for longer range requirements.

Considering the space limitations inside the bus, we optimize the use of space when designing the battery pack to ensure it meets energy requirements while fitting the vehicle's structural layout.

We discussed a lot of technical issues. The vehicle information, vehicle speed, and mileage requirements are super essential for us to develop an EV battery solution for bus. Our engineers will calculate and simulate the LiFoP4 battery capacity. In addition, what kind of certification required by the customer is also important for the whole solution design.

During the cooperation, our team refined the technical aspects, including designing the BMS, drawing circuit diagrams, and arranging the routes between battery packs and between the battery pack system and the external environment. We selected connectors based on the requirements of power and current.

The performance of the charging gun shall match the charging port within the battery pack system. The DC fast charging station and the battery pack were tested for charging functionality before shipment. As the charging method is European standard, we needed conduct joint debugging before shipment.

After shipment, we provided client with software technical services and online remote technical support. After the client received the goods, they need our remote technical assistance to install control software for testing. There were compatibility issues with the computer, which were resolved through various troubleshooting methods.

Later Brogen has updated the software several times, and had assisted the client with re-flashing remotely. Now, this Turkish manufacturer is conducting various road condition tests in the later stages.

Last but not least, we have helped our customer apply for and obtain a stringent certification ECE R100, which is necessary for vehicles go to the European market. For more information about world vehicle regulation please click here.

At Brogen, we're committed to offering custom EV solutions. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

We have delivered high-quality electric powertrain solutions to over 100 customers across more than 20 countries.

Get in Touch with Our Experts

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube.

For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual