Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

In a new wave of technological change and industrial upgrading, the commercial vehicle field is experiencing an unprecedented technological transformation.

As the core component of BEV and HEV in commercial vehicles field, the electric drive axle has attracted much attention for its technological evolution and market application prospects.

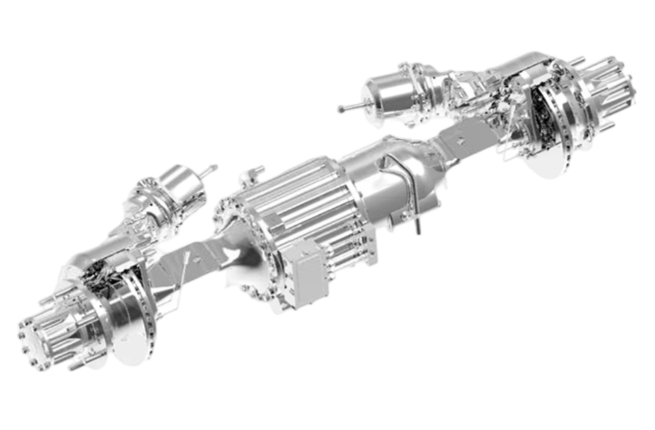

The development of electric drive axle technology can be divided into three generations: starting from the early central single-motor drive mode, gradually transitioning to central dual-motor drive to improve power performance and efficiency, and then moving to a new stage of highly integrated design.

At present, the technical paths of electric drive axles are mainly divided into two directions: centralized and distributed. Each of them provides diversified power solutions for BEVs and HEVs with its unique advantages.

Brogen offers different types of electric drive axles to meet your different application needs.

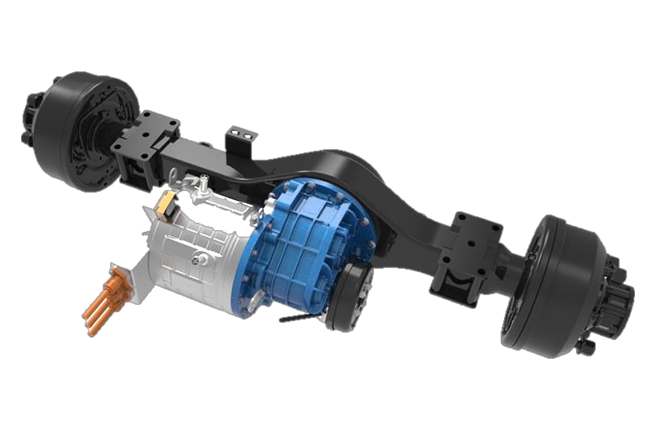

The centralized electric drive axle achieves a high degree of integration of the drive axle, motor, and transmission by eliminating the transmission shaft. This significantly reduces the space occupied and the vehicle's weight, improves transmission efficiency, and enhances the vehicle's dynamic response and driving ability. It has higher compatibility, a simpler structure, and more cost - advantage. At present, centralized electric drive axles are widely used in medium and heavy trucks.

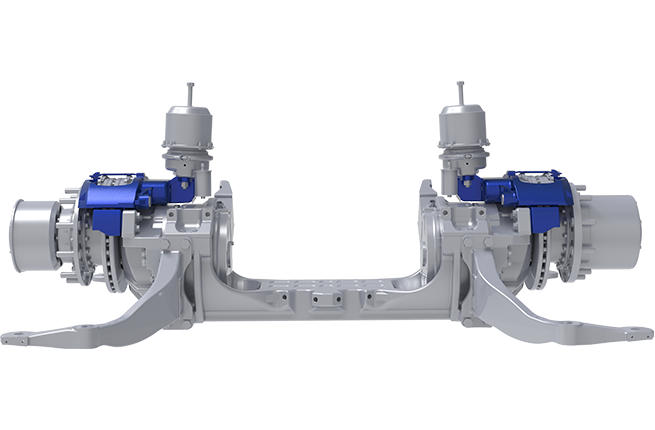

Distributed electric drive axles provide diversified power solutions in the field of electric vehicles with their advantages of direct power transmission, improved efficiency, and control performance. Distributed electric axles are widely used in urban public transportation that pursues low - floor designs.

The parallel - axis electric drive axle (single motor) is the current mainstream technical solution. It is very cost-effective.

Due to structural limitations, the coaxial electric drive axle poses certain constraints on the design of the motor and box, resulting in a relatively limited load - bearing capacity. It is mainly suitable for lightweight trucks and vans.

At present, a variety of integrated solutions have emerged for drive systems, including “2 in 1” assembly (motor + reducer), “3 in 1” assembly (motor + reducer + motor controller), and even higher integration levels “all-in-one” assembly. Brogen's all - in - one drive assembly is mainly suitable for small passenger cars.

Nowadays many OEMs and internationally renowned parts suppliers such as Bosch and ZF are actively developing and applying electric drive axle products to further promote the rapid development of the electric commercial vehicle industry.

In addition to traditional commercial vehicle fields such as heavy trucks and light trucks, its application will also extend to pickup trucks, small size trucks, and micro vans.

At Brogen, we're committed to offering custom EV solutions. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube. For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual