Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

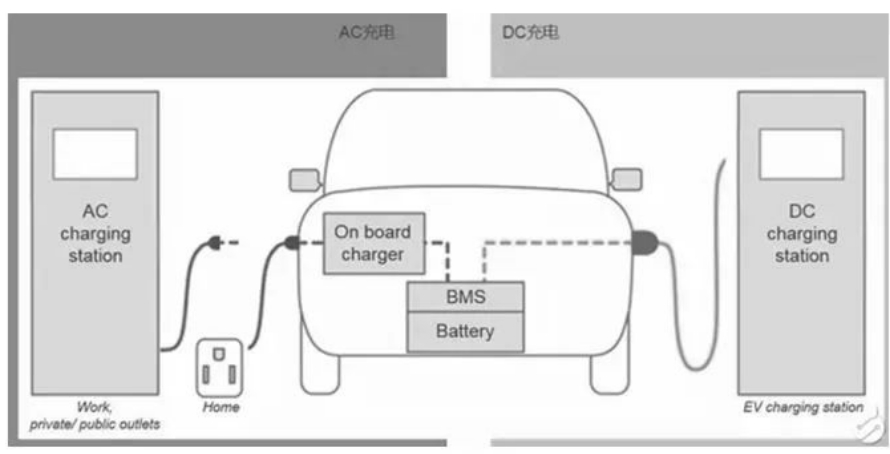

Electric vehicles (EVs) can be categorized into five types based on charging methods: Hybrid Electric Vehicles (HEV), Plug-in Hybrid Electric Vehicles (PHEV), Extended-Range Hybrid Electric Vehicles (EREV), Battery Electric Vehicles (BEV), and Fuel Cell Electric Vehicles (FCEV). PHEVs, EREVs, BEVs, and FCEVs require external charging, necessitating an On-Board Charger (OBC).

The OBC, also known as the AC charger, is a crucial component of the slow charging system for EVs. It can handle single-phase or three-phase power, delivering up to 22kW for rapid charging. Since batteries are charged with DC power, the OBC's primary role is to convert AC input into a DC charging voltage suitable for the battery, typically around 400V, with an increasing trend towards 800V for future models.

To ensure safe, reliable, and automatic charging, the OBC adjusts parameters like charging current or voltage based on data from the Vehicle Control Unit (VCU) and Battery Management System (BMS). This ensures the power battery's charging requirements are met.

The OBC connects to the slow charging port and the high-voltage control box. It communicates with the VCU and BMS. To protect electronic components, it features DC output terminals, AC input terminals, low-voltage communication terminals, heat sinks, and cooling fans.

This terminal connects to the power battery via the high-voltage control box. Pin A is the negative output, and Pin B is the positive output.

This terminal connects to the slow charging port. Pin 1 links to the L (AC phase), Pin 2 to the N (neutral), Pin 3 to the PE (ground), Pin 4 is unused, Pin 5 to the CC (charging confirmation), and Pin 6 to the CP (control pilot).

During high-current, long-duration charging, the OBC generates heat. To prevent damage, it reduces charging current if cooling is inadequate. OBCs typically use air cooling, while integrated chargers may use water cooling.

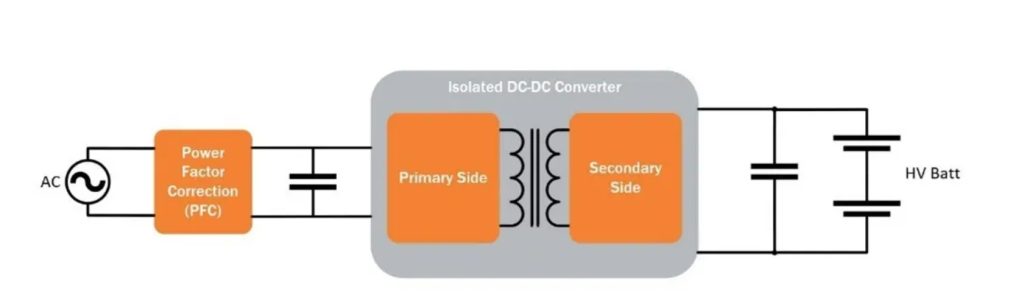

The OBC converts 220V AC to a stable DC voltage, then to high-frequency AC, and finally to the appropriate DC charging voltage. This process reduces size, weight, and improves efficiency compared to traditional transformers.

The control circuit acts as the "brain," managing the main circuit's operations.

The main circuit converts 220V AC to the required DC voltage, with PFC (Power Factor Correction) and LLC (LLC Resonant Circuit) for efficiency and power density.

To prevent damage from overcurrent and overvoltage, the OBC includes:

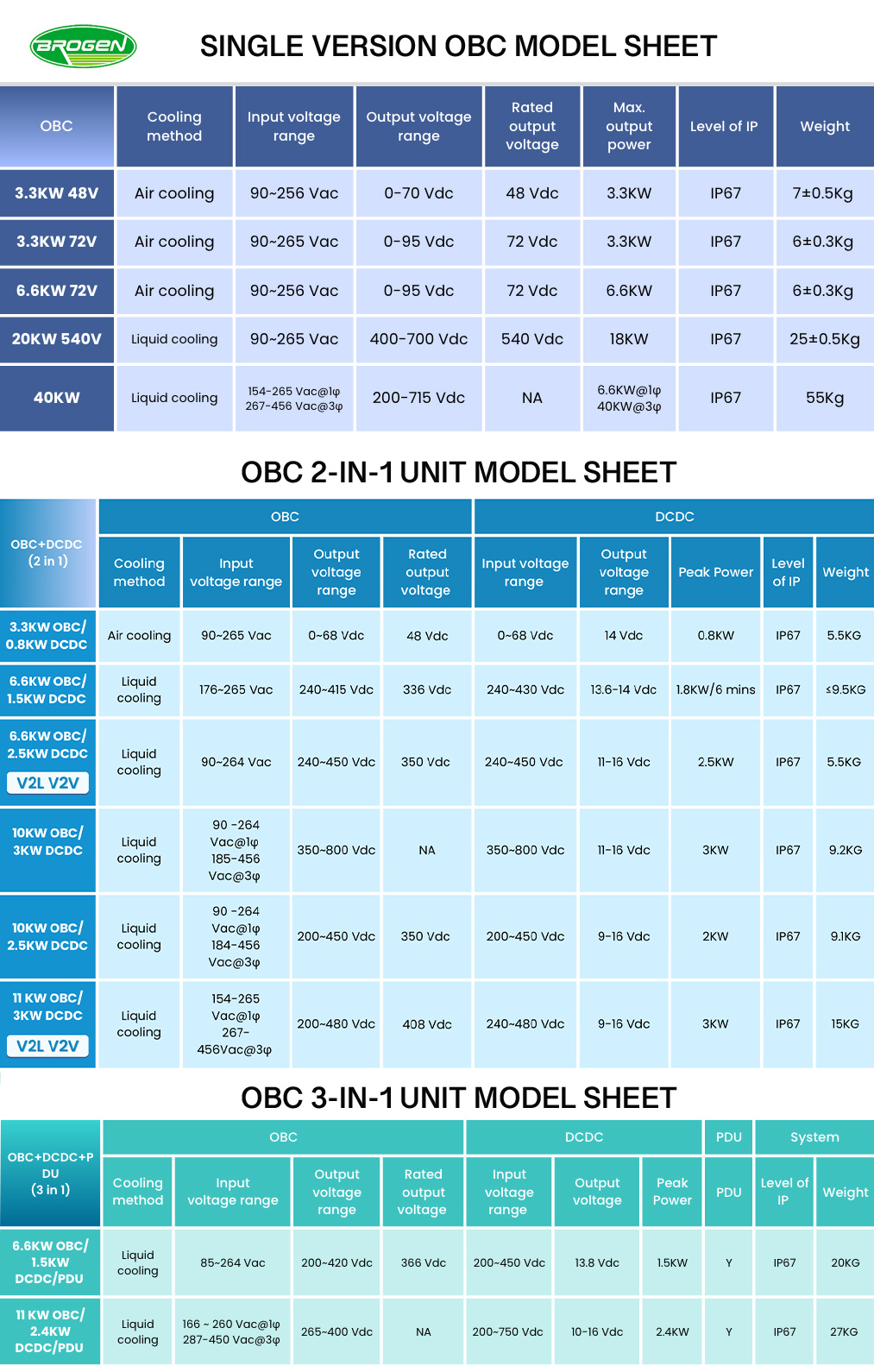

Brogen's OBC is designed for BEVs, with variety power options: 3.3kW, 6.6KW, 11KW,20KW and 40KW. There are single OBC and 2 in 1 and 3 in i models for your choose to fit your new energy car charging.

At Brogen, we're committed to offering custom EV solutions and boosting your electric vehicle manufacturing. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

We have delivered high-quality electric powertrain solutions to over 100 customers across more than 20 countries.

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube.

For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual