Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

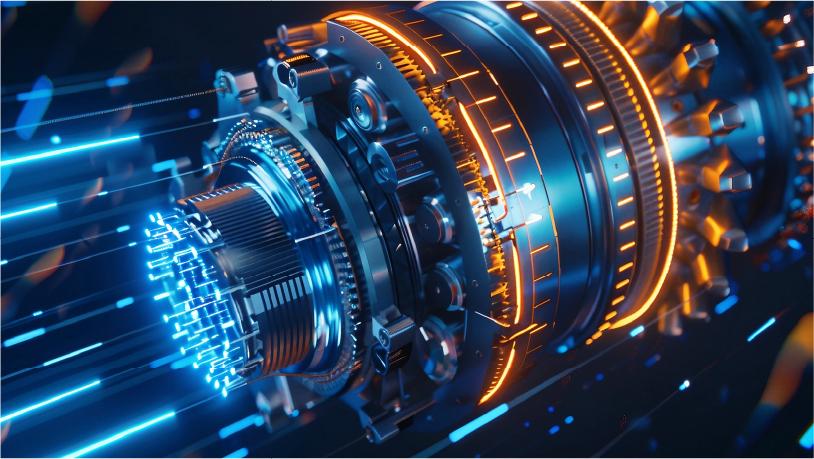

Maximize transmission efficiency to 98.6% with advanced techenology, precise gearing and a modular design.

The axle boasts a peak output torque of 51,480 N·m, with the motor capable of the same feedback torque.

In a 4x2 tractor, the distributed drive saves 462KG over direct drive and 300KG over integrated axles, enhancing payload.

Our integrated and distributed axle offers exceptional durability, with a B10 life expectancy of 1.6 million kilometers.

The parallel axis design often results in a more direct power transfer path, reducing energy loss and enhancing transmission efficiency.

These axles are engineered to be compact, saving space and allowing for greater flexibility in vehicle layout design.

The design is typically compatible with existing suspension and chassis systems, making it easier to integrate into current vehicle architectures.

The drive axle delivers substantial torque directly at the wheel, which is crucial for applications requiring high starting torque.

This System ensures full torque support and boosts range by over 15% in energy efficiency.

Saves chassis space, reduces weight by over 100KG, increases passenger capacity by over 30%.

Symmetrical layout ensures a balanced distribution of unsprung mass, minimizing the impact on suspension stress.

Precision-ground gears have low noise. The cab noise does not exceed 70dB, and the driving experience is more comfortable.

Our advanced EMB system provides maximum 22,000Nm braking torque, saves 40% space, lightens the vehicle by 50%, and enables quick braking with shorter braking distance by 10m.

| Model | Applicable models | Rated axle load capacity | Motor power | Max. output torque |

| OEEP6 | 5 m - 6 m bus; minibus | 3500 kg | 60/130 kW | 5700 N·m |

| OEEP8 | 6 m - 7.2 m bus | 5500 kg | 90/160 kW | 7285 N·m |

| OEEP31 | 8 m - 8.5 m bus | 8500 kg | 80/150 kW | 13000 N·m |

| Model | Applicable models | Rated axle load capacity | Motor parameters | Max. output torque |

| OESTEA4200Z | 3.5 T - 4.5 T truck; 6 m bus | 2500 kg | 60/110 kW; 150/350 N.m | 4200 N·m |

| OESTEA5300Z | 4.5 T - 6.0 T truck; 6 m bus | 3500 kg | 60/120 kW; 145/335 N.m | 5300 N·m |

| OEEA30 | light bus; miniature truck | 3000-3500 kg | 60/120 kW; 160/350 N.m | 4433 N.m |

| OEEA60 | 7m road vehicle; power light truck | 6000 kg | 80/160 kW; 235/450 N.m | 7412 N.m |

| OEEA85 | 8 m bus/road vehicle | 6000-8500 kg | 80/160 kW; 200/450 N.m | 9214 N.m |

| OEEA95 | 9 m road vehicle; 10.5 m bus; 11 m road vehicle | 9500 kg | 200/320 kW; 350/750 N.m | 14415 N.m |

| OEEA100 | 49 T/80 T tractor; 38 T/45 T mixer and 32 T sanitation vehicle | 10000-13000 kg | 200/320 kW; 350/750 N.m | 41400 N.m |

| OESTEA4000Z | 4x2/6x4 tractor; 18 T municipal vehicle | 13000 kg | 125/250 kW; 350/800 N.m | 41690 N·m |

| OEEP5A (front axle steering) | 4.5 T - 6.0 T truck; 5 m - 6 m bus | 2700 kg | 60/115 kW; 135/350 N.m | 5400 N·m |

| Model | Applicable models | Rated axle load capacity | Motor max. power | Max. output torque |

| OEEA850F | Tourist bus, light-duty truck | 5000 kg | 2x74 kW | 2x4060 N·m |

| OEEA1100K | Virtual rail metros with rubber-tire | 9000 kg | 2x90 kW | 2x6142 N·m |

| OEC14000L | 8 m - 9 m bus | 9000 kg | 2x120 kW | 2x7020 N·m |

| OEEA2100N | 10.5 m - 18 m bus | 13000 kg | 2x160 kW | 2x10776 N·m |

| OEEA2100P | Airport shuttle bus | 14000 kg | 2x160 kW | 2x10776 N·m |

| OEEA5000N | 4x2/6x2/6x4 tractor, 4x2/8x4/6x2 truck | 13000 kg | 2x180 kW | 2x25000 N·m |

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual