Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

From the development trend of electric drive system technology for new energy vehicles at home and abroad, the overall trend is towards the integration and integration of power systems.

Major automakers such as BYD, Tesla, GM, and Geely have integrated drive motors, motor controllers, and reducers as electric drive assembly products as the next key development direction. Today, let's take a look at the various electric drive axles currently on the market and their characteristics.

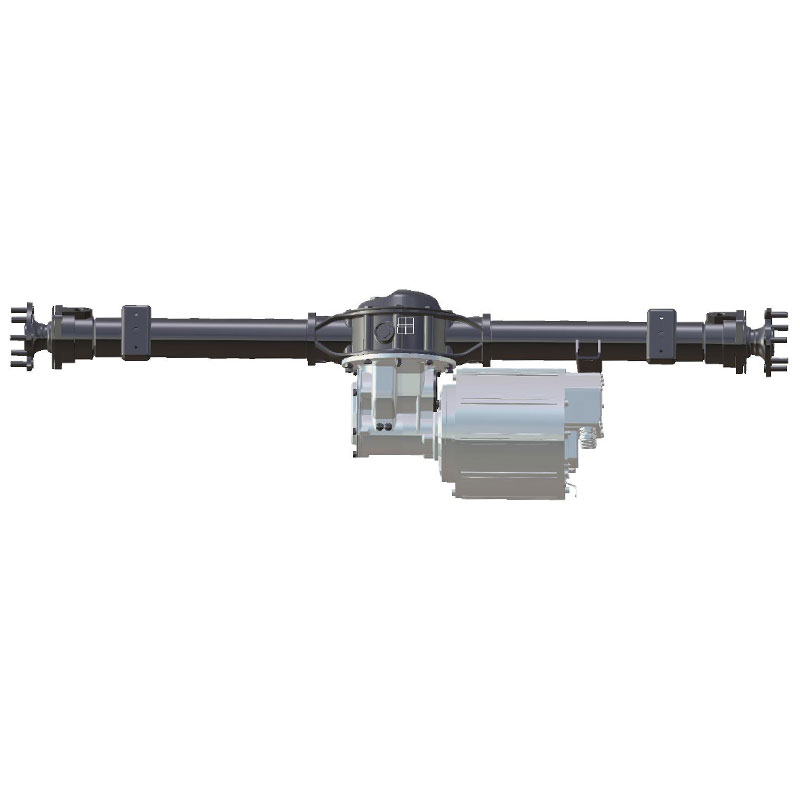

The characteristics of a half rear axle include its simple structure, lower cost, and ease of maintenance, which is why it is widely used in many traditional fuel vehicles. However, with the development of new energy vehicle technology, the drive axle is also being adapted to new powertrain requirements. For example, by integrating motors and reducers, electric drive can be achieved.

Features: Low system efficiency; High development and manufacturing costs; Large space occupation, making it difficult to arrange the power battery pack; Good NVH performance of the vehicle; Heavy weight.

Main manufacturers: BAIC New Energy, FAW Jilin Light Automobile Factory

The drive motor is integrated with the transmission, replacing the original engine and transmission, to leverage the high-speed advantages of the electric motor.

Features: Low system efficiency; Low development difficulty and low manufacturing costs; Large space occupation, making it difficult to arrange the power battery pack; System weight is comparable to the former.

Main manufacturers: ZF, GKN, YJAS

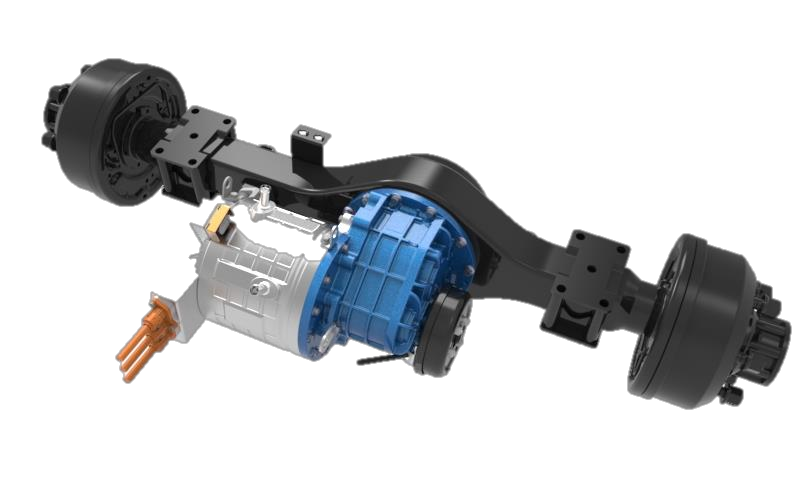

The motor is integrated with the traditional drive axle, and after reduction and torque increase, it directly drives the wheels.

Features: Saves components such as drive shafts and suspension brackets, light weight, low vehicle installation cost; High transmission efficiency and small space occupation, facilitating the arrangement of the power battery pack; Poor NVH performance; Large and offset unspring weight, not conducive to vehicle handling.

Parallel shaft electric drive axles are increasingly used in light and medium commercial vehicles, with a later application due to the need for new development of reducers, which is not as convenient as the half-shaft type. Parallel shaft electric drive axles have their own advantages, such as the axle housing and wheel edge and brake parts directly using the mature structure of fuel vehicles, which is reliable; the second is good load bearing and overload capacity. The disadvantage is the heavy unspring mass, affecting comfort.

Main manufacturers: ZF

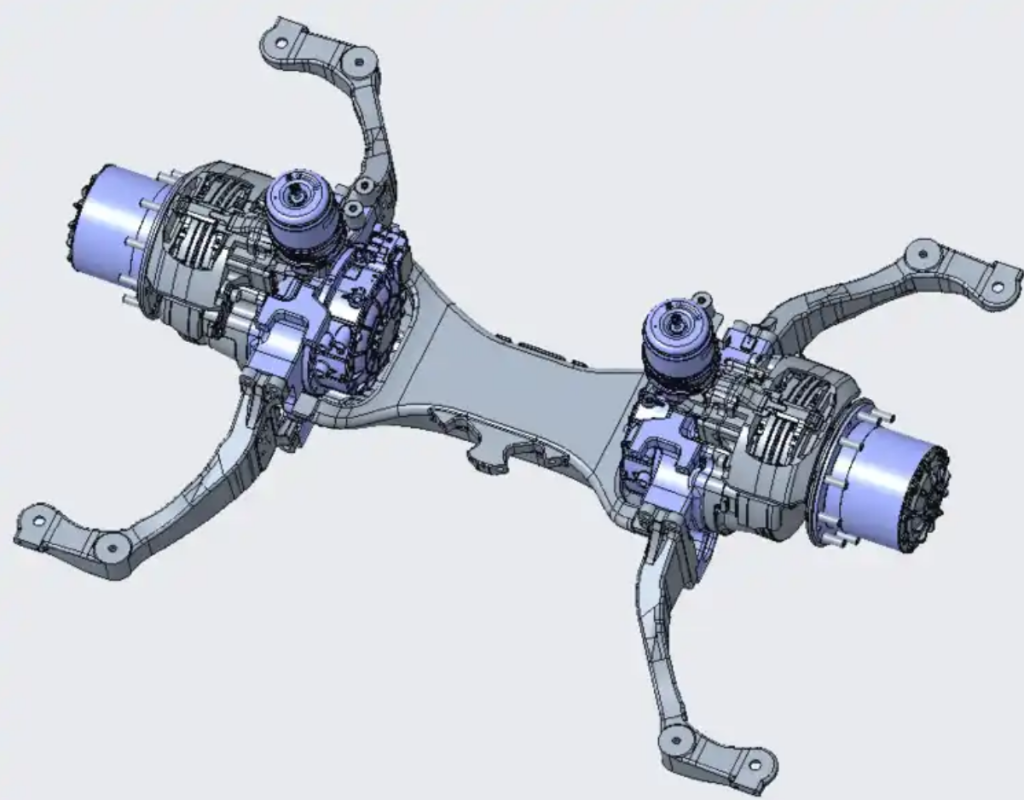

The motor is highly integrated with the reducer and traditional drive axle, releasing underfloor space, eliminating the drive shaft, and facilitating vehicle layout.

Features: Suitable for pure electric buses with high transmission efficiency; Small space occupation, facilitating the arrangement of the power battery pack; Large unspring weight, not conducive to vehicle handling.

Main manufacturers: ZF, BYD, Meritor

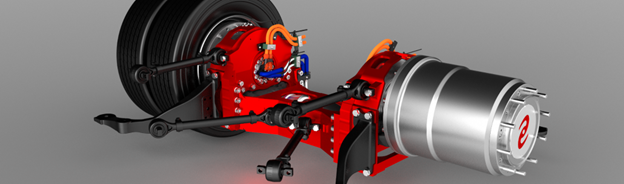

The direct drive in-wheel motor is highly integrated with the drive axle, and the motor directly drives the wheels for power transmission, representing the future direction of drive development.

Main manufacturers: Dutch e-Traction company

Features: The highest transmission efficiency; Small size, light weight, low energy consumption; Braking energy recovery efficiency close to 100% due to the large outer diameter size of the motor, currently only suitable for electric buses and large trucks.

At present, parallel shaft electric drive axles are most widely used in passenger cars, with direct drive (with reducer) schemes more often used by light trucks; wheel-edge electric drive axles, due to their higher technical difficulty, are currently mainly used in buses, such as BYD; the direct drive in-wheel motor axles have not yet been commercialized and are mainly used in prototypes.

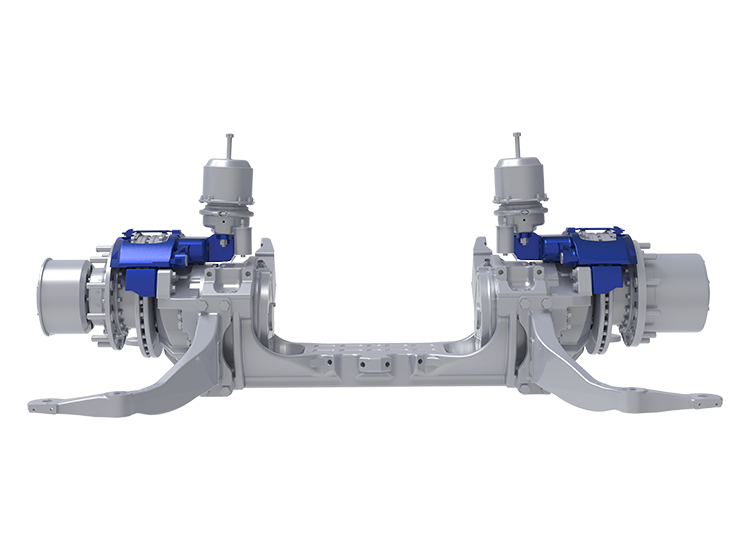

Brogen supplies variety electric axles for different kinds of vehicles including vans, buses, LDVs, HDVs, sanitation vehicles, sweepers, construction vehicles and so on . We are able to provide customizable opitions for your unique requirements. Below is one model of wheel side e axles and its specifications.

| Item | Parameters | |

| Motor | Motor type | PMSM Motor |

| Rated/Peak power (kw) | 2*160/2*95 | |

| Rated torque (N.m) | 2*580/2*220 | |

| Max. speed (rpm) | 8000 | |

| Protection level | IP68 | |

| System | Axle weight | 1080kg |

| Rated axle load | 13000kg | |

| Max. wheel speed (rpm) | 430 | |

| Gear ratio | 18.58 |

This mature and stable e axle can achieve a low floor design, improving interior safety and comfort. It has E-Mark certification and is the best choice for articulated and double decker vehicles. It has reliable EDS(electronic differential system) and can realize tire change mileage exceeding 100 000 kilometers.

At Brogen, we're committed to offering custom EV solutions. We back these with new technologies to help EV companies thrive and promote environmental sustainability. Brogen provides an industry-leading EV Powertrain solution for commercial vehicles.

We've forged strategic alliances with key players in the new energy vehicle sector, including electric motor and controller manufacturers, battery pack producers, and charging station suppliers. We also collaborate with suppliers of essential components such as EV car battery, electric vehicle motor(PMSM motor), motor controller, OBC+DCDC+PDU, axial flux motor, BMS, air conditioning systems, air compressors, and power steering systems.

We have delivered high-quality electric powertrain solutions to over 100 customers across more than 20 countries.

Get in Touch with Our Experts

Are you interested in empowering your EV project? Reach out to our experts at inquiry@brogenmotors.com. We promise to get back to you within two business days.

For more videos please click Brogen’s Youtube.

For the latest news please view Brogen’s Linkedin.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Product Manual