Brogen

- Email:inquiry@brogenmotors.com

- Whatsapp:+86 19352135902

- Wechat:Brogenmotors_SH

- Tel:+86 19352135902

Brogen

Open circuit voltage (OCV): refers to the voltage of the battery when there is no external circuit or external load connected. The open circuit voltage has a certain relationship with the remaining energy of the battery, and the power display uses this principle.

Working voltage (WV): refers to the potential difference between the positive and negative electrodes of the battery when the battery is in working state, that is, when current flows through the circuit. In the battery discharge working state, when the current flows through the battery, it must overcome the resistance of the internal resistance, so the working voltage is always lower than the open circuit voltage.

Discharge cut-off voltage (DCV): refers to the voltage reached when the battery is fully charged and discharged (if it continues to discharge, it is over-discharge, which will damage the life and performance of the battery). Charge limit voltage (LCV): the voltage at which constant current changes to constant voltage charging during charging.

Battery capacity refers to the amount of electricity that the battery can store. Capacity is an important indicator of battery electrical performance, which is determined by the active material of the electrode.

Capacity is represented by C, and the unit is Ah (ampere-hour) or mAh (milliampere-hour): Formula: C=It, that is, battery capacity (Ah) = current (A) x discharge time (h). A battery with a capacity of 10 ampere-hours can be discharged for 2 hours at 5 amperes and for 1 hour at 10 amperes.

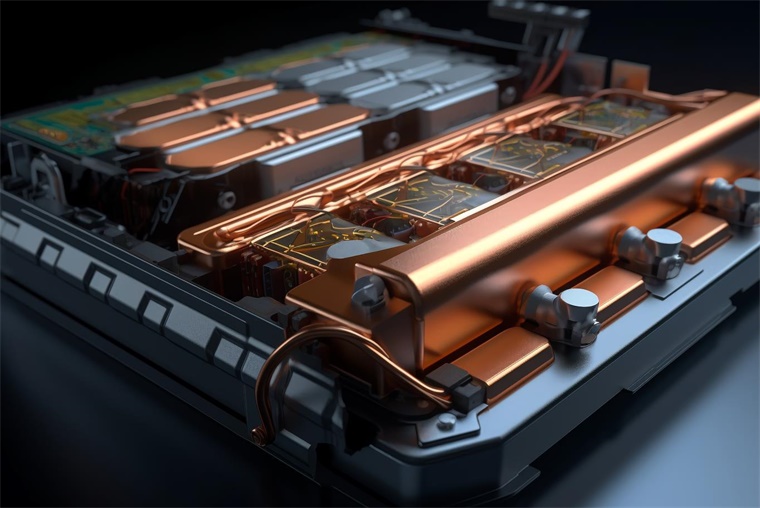

The internal resistance of a battery refers to the resistance encountered by the current flowing through the battery when the battery is working. The size of the internal resistance is mainly affected by factors such as the battery material, manufacturing process, and battery structure. Due to the existence of internal resistance, when the battery is discharged, the current passing through the internal resistance will generate heat and consume energy. The larger the current, the more energy is consumed. Therefore, the smaller the internal resistance, the better the battery performance. Not only is the actual working voltage of the battery high, but the energy consumed on the internal resistance is also less.

The existence of internal resistance makes the terminal voltage of the battery lower than the battery electromotive force and open circuit voltage during discharge, and the terminal voltage higher than the electromotive force and open circuit voltage during charging.

The internal resistance of the battery is not a constant (resistance is divided into physical internal resistance and polarization internal resistance). It changes over time during the discharge process because the composition of the active material, electrolyte concentration and temperature are constantly changing. Ohmic resistance obeys Ohm's law: polarization resistance increases with the increase of current density, but it is not a linear relationship. It often increases linearly with the increase of the logarithm of current density.

When the positive and negative ends of the battery are connected to the electrical appliance, the output power when the electrical appliance is driven to work is the load capacity of the battery.

Refers to the internal air pressure of the battery, which is caused by the gas generated by the sealed battery during the charging and discharging process. It is mainly affected by factors such as battery materials, manufacturing processes, and battery structures.

The main reason for its generation is that the gas generated by the decomposition of water and organic solutions inside the battery gathers in the battery

C is the first letter of Capacity, which is used to indicate the value of the current when the battery is charged and discharged.

For example: when the rated capacity of a rechargeable battery is 1100mAh, it means that the discharge time at 1100mAh (1C) can last for 1 hour, and if the discharge time at 200mA (0.2C) can last for 5 hours. The charging can also be calculated in this way.

If the battery exceeds the termination voltage of the battery discharge during the discharge process and continues to discharge, it may cause the internal pressure of the battery to increase, the reversibility of the positive and negative active materials to be damaged, and the battery capacity to be significantly reduced.

When the battery is charged, if it continues to charge after reaching the full state, it may cause the internal pressure of the battery to increase, the battery to deform, leak, etc., and the performance of the battery will be significantly reduced and damaged.

The method of expressing the value of the battery's retained capacity. The depth of charge and discharge is expressed in percentage.

For example: if the capacity of a battery with a capacity of 10Ah becomes 2Ah after discharge, it can be called 80% DOD. For example: a battery with a capacity of 10Ah has a capacity of 8Ah after charging, 80% SOC. Describing full charge and discharge, it is usually called 100% DOD.

The discharge rate refers to the current value required to discharge its rated capacity (C) within a specified time, which is numerically equal to the multiple of the rated capacity of the battery.

According to the size of the discharge rate, it can be divided into low rate (<0.5C), medium rate (0.5-3.5C), high rate (3.5-7.0C), and ultra-high rate (>7.0C)

Take a 10Ah battery as an example: If it is discharged at 2A, the discharge rate is 0.2C. If it is discharged at 20A, the discharge rate is 2C.

Definition: refers to the amount of energy stored in the battery, expressed in Wh

Formula: Energy (Wh) = rated voltage (V) x working current (A) x working time (h).

For example: the energy of a 3.2V15Ah single cell is 48Wh, and the energy of a 3.2V100Ah battery pack is 320Wh. Battery energy is an important indicator for measuring the work done by the battery to drive the equipment. The capacity cannot determine the amount of work done.

Concept: A secondary battery undergoes a charge and discharge cycle called a cycle or a cycle. After repeated charge and discharge, the capacity of the battery will gradually decrease. Under certain discharge conditions, when the battery capacity drops to 80%, the number of cycles the battery has undergone is the cycle life.

The cycle life is related to the battery charging and discharging conditions: the 0.5C charge and discharge cycle life of lithium-ion batteries at room temperature can reach 3000-5000 times (industry standard). Influencing factors: Improper use of batteries, battery materials, electrolyte composition and concentration, charge and discharge rate, depth of discharge (DOD%), temperature, manufacturing process, etc. all have an impact on the battery cycle life.

Refers to the energy released per unit volume or mass, usually expressed as volume energy density (Wh/L) or mass energy density (Wh/kg).

For example, if a lithium battery weighs 325g, has a rated voltage of 3.7V and a capacity of 10Ah, its energy density is 113Wh/kg. The following table shows the theoretical values. In actual applications, various factors such as the shell and parts in the battery structure need to be considered.

At present, the energy density of lithium batteries is 3 and 1.5 times that of nickel-cadmium and nickel-metal hydride batteries. The energy density is determined by the material density and structure.

Charging time (hours) = rechargeable battery capacity (mAh)/charging current (mA)*1.5 coefficient.

If you use a 1600mAh rechargeable battery and the charger charges with a current of 400mA, the charging time is: 1600/400*1.5=6 hours.

Connect with a Brogen expert to learn more about our services and discuss our ePowertrain solutions.

Company Profile